TM 10-3930-641-34-2

LINES, PLUGS, FITTINGS TORQUE

(Sheet 3 of 11)

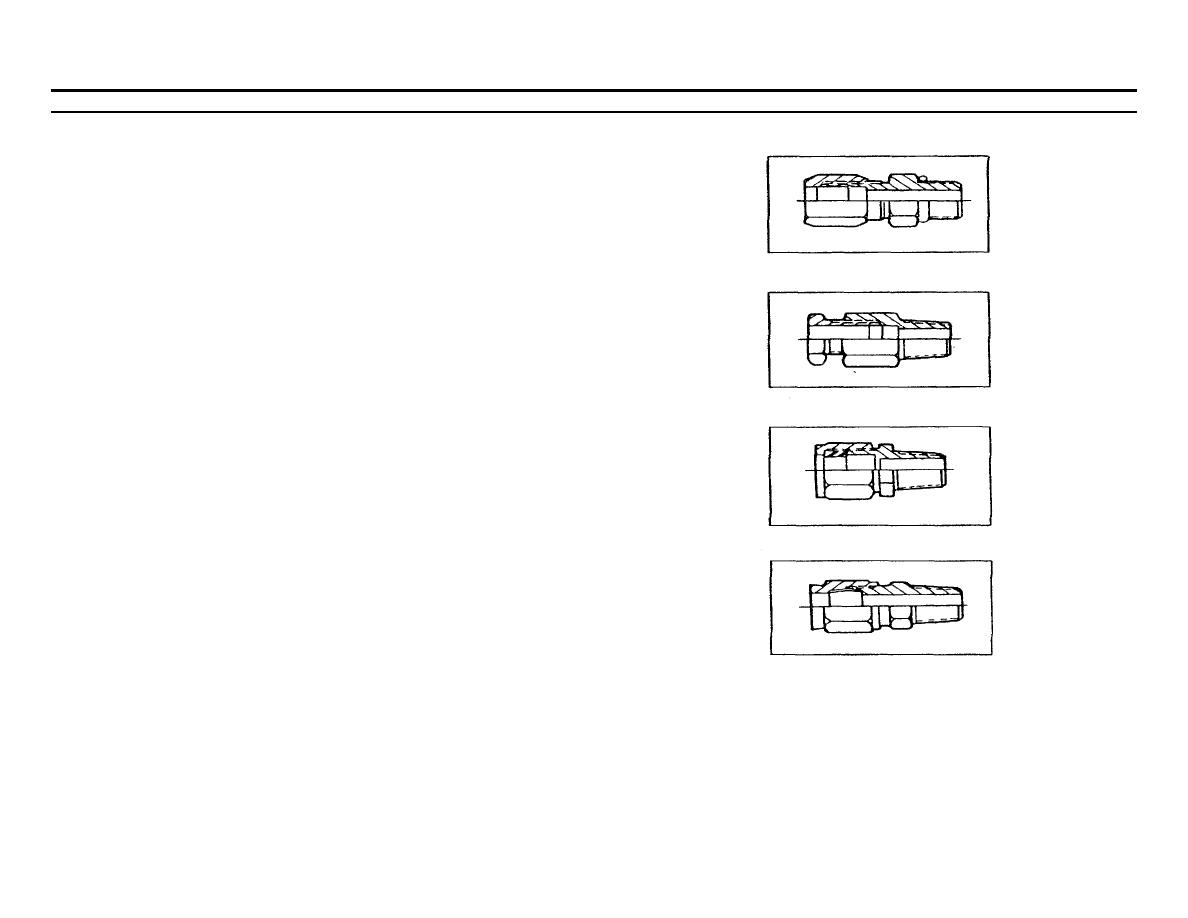

Ermeto Tube Fittings

Put nut and sleeve over the tube with head or shoulder end of sleeve next

to nut. Push tube into counterbore of fitting body as far as possible. Turn nut

clockwise until sleeve holds tube and prevents movement. Tighten the nut

11/4 turns more to seat sleeve and give a locking action. When necessary to

assemble again, put sleeve over tube and tighten nut until a sudden increase

in torque is felt. Then tighten 1/6 to 1/3 turn more to seat the sleeve.

Flex Fittings

Put nut and sleeve over tubing and push tube into counterbore of fitting

body as far as possible. Tighten the nut until it is against 'he hex part of the

fitting body.

Hi Duty (shear sleeve)

Tube Fittings

After tube has been put through the nut and makes contact against the

tube shoulder in the fitting body, turn the nut with a wrench until a small

decrease in torque is felt. This is an indication that the sleeve has been

broken off of the nut. Hold the tube to prevent turning and tighten the nut I

and 1/2 turns.

Hi Seal Fittings

Put nut and sleeve over the tubing with the short heavy end of the sleeve

facing the end of tubing. Put the tube end against the counterbore in the body

of the fitting and tighten until nut is over the last thread on the body. The

remainder of space is used whenever the fitting is removed and installed

again.

Go on to Sheet 4

D-3