TM 5-3810-306-34

INSPECTION:

1. CLEAN AND INSPECT ALL PARTS.

a. When inspecting bearings, keep needles,

caps, and retainers together.

b. Replace parts that show excessive wear

or damage. If it is necessary to use a new

cross, needle bearings should also be

replaced. Do not mix new and used

bearings together. Replacement should

be made in sets of four.

INSTALLATION:

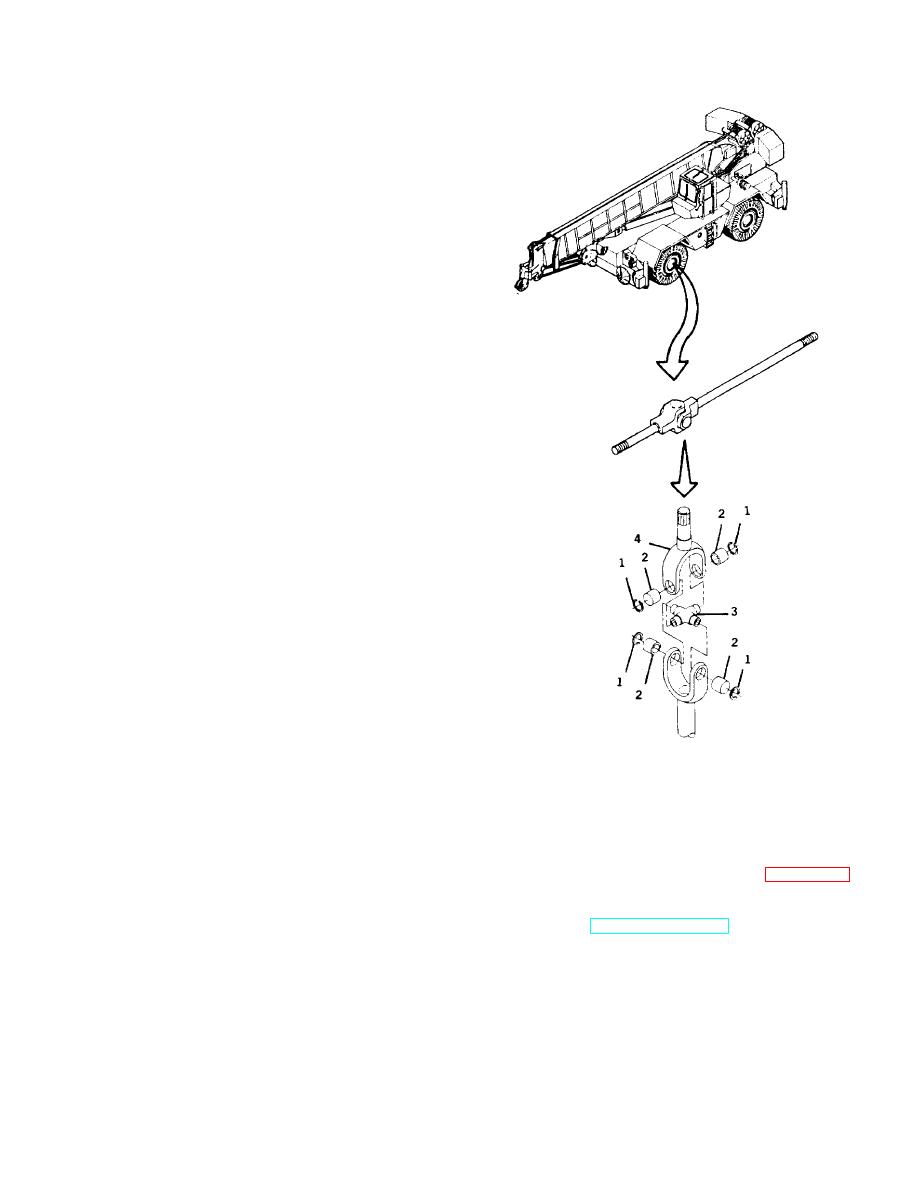

1. INSTALL UNIVERSAL JOINT.

a. Insert needle bearing cap (1) into ear of

yoke.

b. Place yoke in a vise and press needle

baring cap into proper position. (The

bearing cap has a highly polished surface

and care should be exercised not to mar

or scratch surface during installation

operations).

c. Remove yoke from vise and gently work

one arm of cross (3) into yoke (4) and

bearing cap (1).

d. Install opposite bearing cap (1) by hand

and line up cross (3) arm.

e. Place yoke in a vise and press needle

bearing cap (2) into yoke (4) and onto arm

of cross (3).

g. Repeat procedures outlined in Steps a

CAUTION

through f for installing remaining caps and

yokes.

The cross must move freely in both

caps.

If the cross should bind,

2. INSTALL AXLE SHAFT AND UNIVERSAL JOINT IN

remove the cap and check for upset

HOUSING.

needles.

3. INSTALL WHEEL ENDS. (REFER TO PAGE 8-50.)

f. With aid of a short plug, move the bearing caps past

snap ring groove, and insert snap rings (1) into grooves.

4. INSTALL WHEEL AND TIRE

ASSEMBLIES.

(One with each bearing cap).

(REFER TO TM 5-3810-306-20.)

5. TEST FOR PROPER OPERATION.

END OF TASK

8-49