TM 5-3810-306-34

INSTALLATION:

d. To make the measurements, turn on the heater

again and measure the increase in fuel volume

1. INSTALL FUEL (DOSING) PUMP (1).

for two 90 second periods. At the same time,

measure the electrical voltage at the control unit

a. If removed, position clamp (8) on mounting studs

terminals B3 (+) and C2 (-).

and secure with two new lockwashers (7) and

nuts (6).

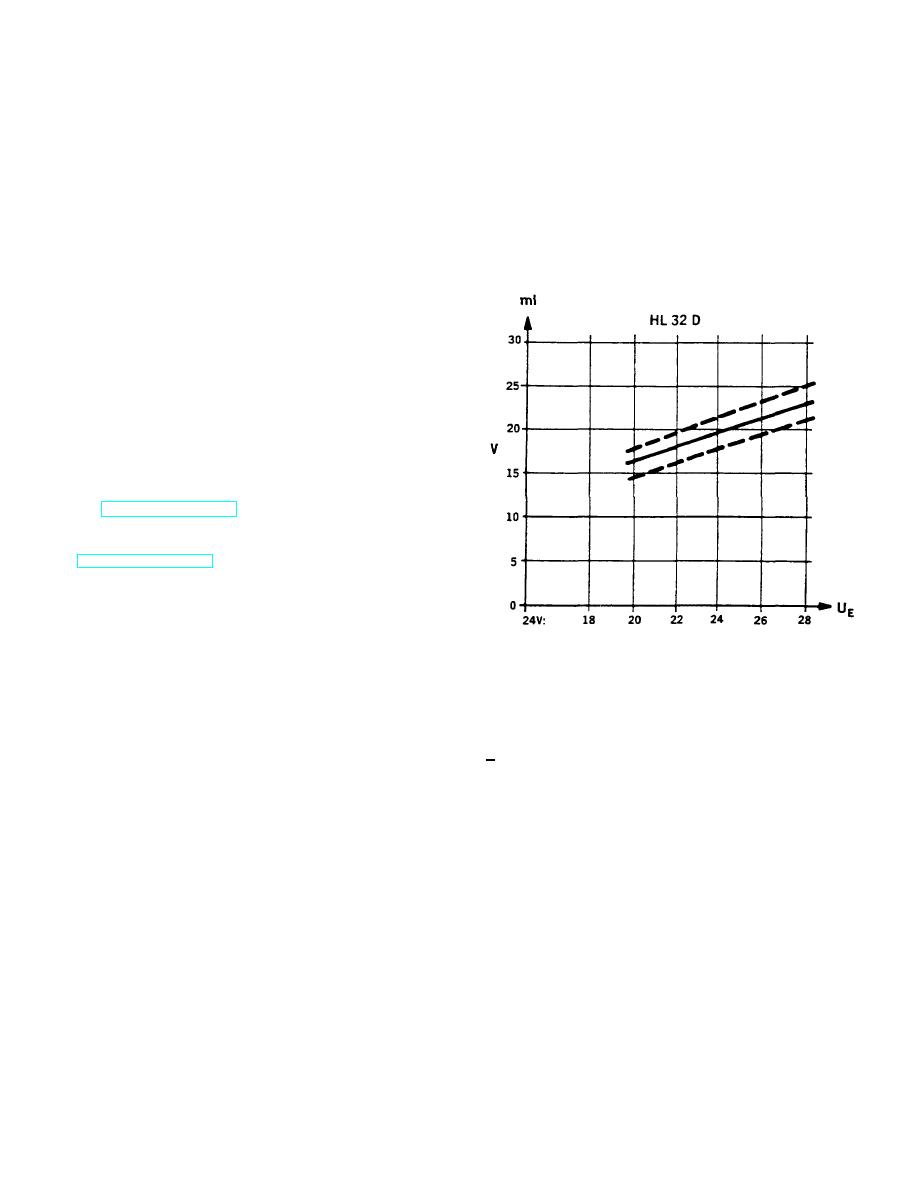

e. Take the data recorded in step d and apply it to

the following graph. The point of intersection

b. Slide bumper (9) and pump (1) into clamp (8)

must lie within the shaded area.

and tighten.

c. Slip hose (5) over fitting on pump and secure

with hose clamp (4).

d. Slip hose (3) over fitting on pump and secure

with hose clamp (2).

e. Connect electrical leads to pump and marked

during removal.

2. OPEN PETCOCK ON BOTTOM OF HEATER FUEL

TANK.

3. CONNECT GROUND CABLE AT SHUNT. (REFER

TO TM 5-3810-306-20.)

4. CHECK CAB HEATER OPERATION. (REFER TO

TM 5-3810-306-10.)

CHECKING PUMP FLOW RATE:

1. CHECK FLOW RATE AS FOLLOWS:

a. Remove wiring harness cap from top of heater

and disconnect glow plug.

Delivery volume V (ml) of the dosing pump after 180

seconds pumping time plotted against the input voltage

b. Detach the fuel line from the heater and place

U (V) at the electronic control unit. Temperature T= +20

the end of it in a measuring cylinder such as a

+2 (C).

100 ml graduated burette.

c. Turn on heater. After 90 seconds, the heater

automatically goes to fault lock-out with

subsequent repeat start. Repeat this procedure

until fuel emerges from fuel line.

12-9