TM 9-3990-260-14&P

Table 4-1. Unit Maintenance Preventive Maintenance Checks and Services - Continued

Location

Item

Interval

Procedure

Not Fully Mission

Item to

No.

Capable If:

Check/Service

3

Semi-

Bracing

d. Ensure each securing pin can be

d. Cam securing pin

(Cont)

Annually

Mechanisms

inserted through its cam and cam can be hole is deformed or pin

properly secured.

cannot otherwise be

inserted through cam

and properly secured.

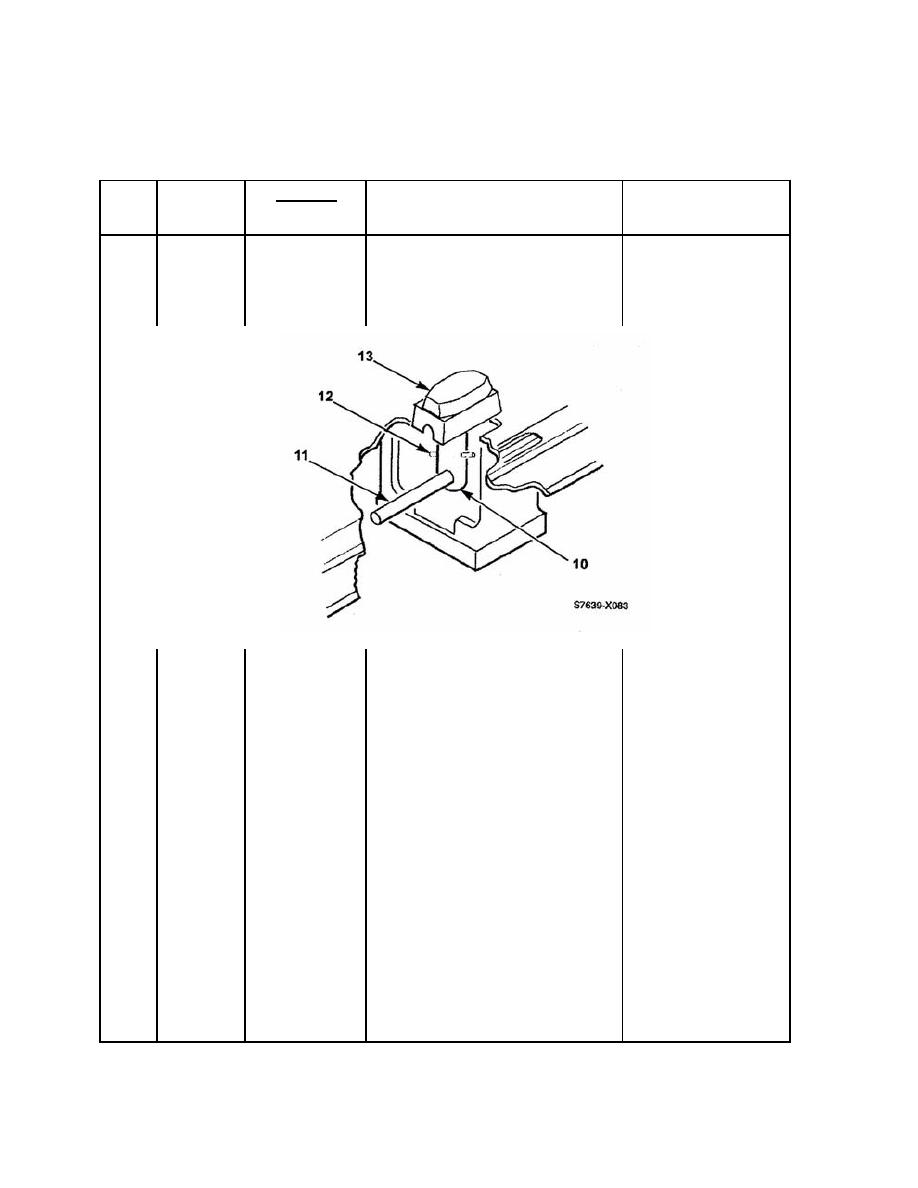

4

Semi-

Visually inspect twistlocks to ensure:

M3 CROP

Annually

Twistlocks

a. Shaft is broken.

a. The shaft (10) is straight and not

cracked or broken.

b. Handle is missing.

b. Handle (11) is securely fastened to

shaft.

c. Shear pin is miss-

c. Shear pin (12) is secure.

ing.

d. Head is broken,

d. Head (13) is not broken or cracked.

cracked or missing.

e. Twistlock can be locked and

e. Twistlock cannot be

locked or unlocked by

unlocked correctly without undue diffi-

hand.

culty.

f. No crack greater than 3/4 inch (19

f. Twist lock housing

mm) exists in the welds or parent mate-

welds or parent material

rial of the twistlock housing.

contains a crack greater

.than 3/4 inch (19 mm).

4-8