TM 10-3930-675-20-2

0166 00-5

TOPHANDLER HYDRAULIC SLEWING MOTORS REPLACEMENT - CONTINUED

0166 00

INSTALLATION

WARNING

•

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during

procedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep

clear of heavy parts supported only by lifting device. Failure to follow this warning may result in death

or injury to personnel.

•

Slewing motor weighs approximately 150 lb (68 kg). Lifting device must have sufficient capacity to lift

motor. Failure to follow this warning may result in injury to personnel.

NOTE

•

Refer to General Maintenance Instructions (WP 0194 00) for complete instructions on connecting

hydraulic hoses and applying proper torque.

•

Ensure slewing motor is oriented to allow hoses or hydraulic manifold connections.

1.

With assistance, and using nylon sling and suitable lifting device, install slewing motor (6) with pinion gear (13) thru

turning plate (1) and engage ring gear (14).

2.

Install ten bolts (11) and washers (12) to secure slewing motor (6) in place. Tighten bolts in an even pattern in accor-

dance with Torque Limits (WP 0198 00).

NOTE

•

To install slewing motor with hydraulic manifold, perform steps 3 and 4.

•

To install slewing motor without hydraulic manifold, proceed to step 5.

•

Ensure o-rings are lubricated with lubricating oil prior to installation.

3.

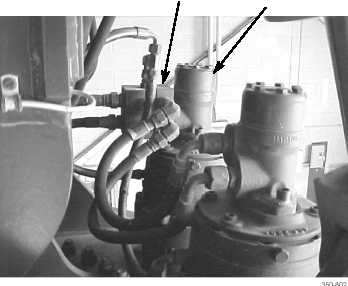

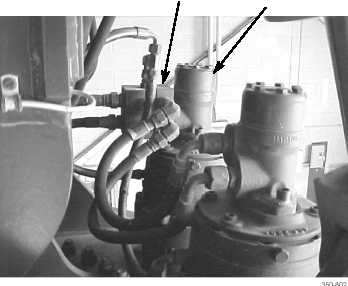

Position new o-rings and hydraulic manifold (5) with hoses attached to slewing motor (6) mating surface.

5

6