TM 10-3930-675-24-1

TROUBLESHOOTING PROCEDURES (NON-ERROR CODE) - CONTINUED

0007 00

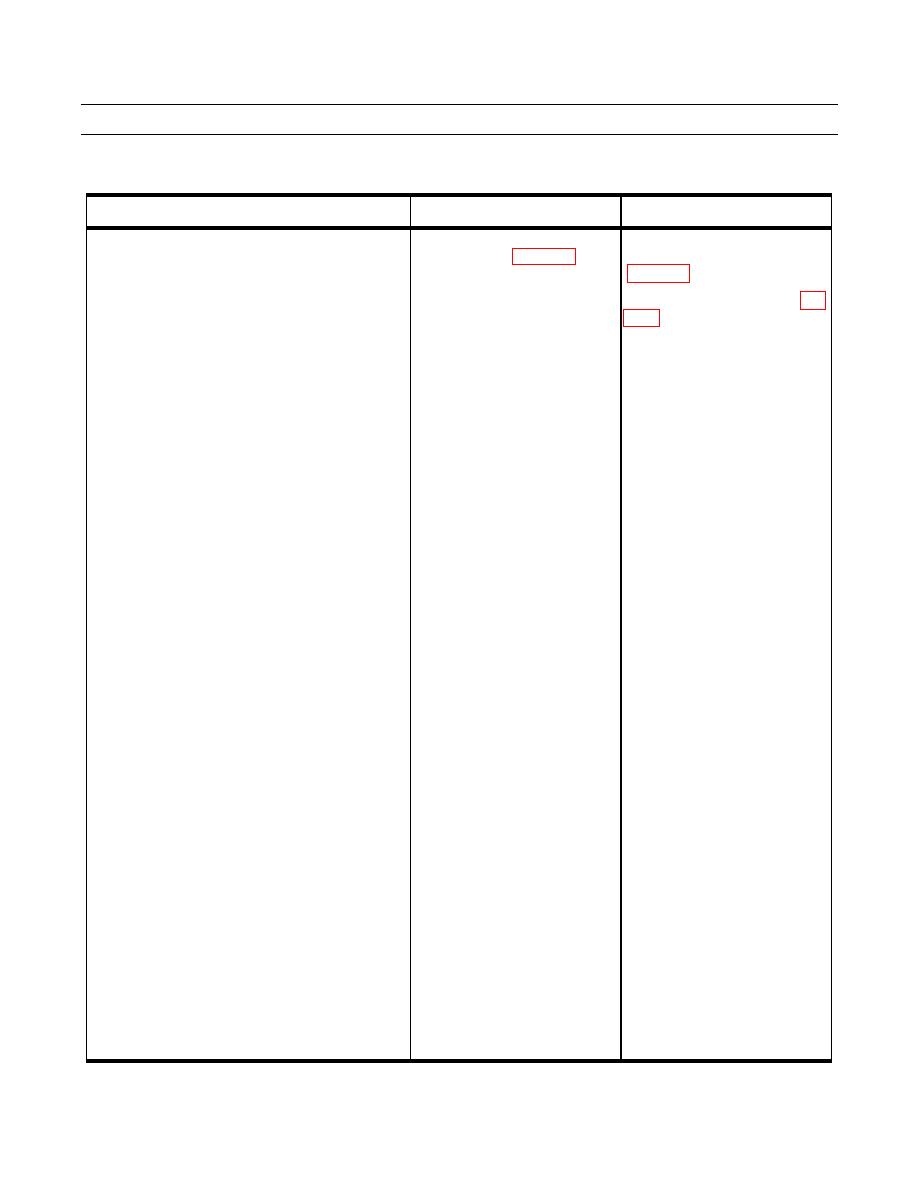

Table 7. Boom System Troubleshooting Procedures (Non-Error Code).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Boom Will Not Lift or Lower Properly.

1. Check for active boom system Perform troubleshooting

error code(s) (WP 0005 00).

procedures to clear error code(s)

(WP 0005 00).

2. Check hydraulic oil level. Fill hydraulic oil as required (WP

Ensure hydraulic oil level is 0050 00).

within operating range (WP

0051 00).

3. Ensure boom locked (red) Use the override switch to move

twistlock indicator light is on. twistlocks into proper position

(TM 10-3930-675-10).

4. Inspect lift cylinders for a. Remove any obstructions.

obstructions, damage, and b. Replace damaged or leaking

signs of leakage.

cylinders (WP 0252 00).

5. Check lift cylinder hydraulic a. Tighten loose connections.

lines and hoses for damage and b. Replace damaged or leaking

signs of leakage.

lines and hoses (WP 0182 00).

6. Ensure lift cylinder emergency Close emergency and float valves

and float valves are in closed as required (TM 10-3930-675-

position.

10).

7. Check boom and tophandler Calibrate boom and tophandler as

calibration (WP 0259 00).

required (WP 0259 00).

8. Check test boom control a. If boom system operates

system. Operate the auxiliary

normally, the boom control

pump using the procedure

system is not at fault, check

"Lower Boom (Extended or

boom and brake pump

Loaded with a Container)"

pressure (WP 0188 00).

(TM 10-3930-675-10) to test b. If boom system does not

boom control system. (The

operate normally, check boom

boom movements will be

control system.

extremely slow).

9. Test boom system operating a. If test point 9 pressure is not

pressures at test points 8 and 9

normal, replace servo pressure

(WP 0188 00).

reducing valve first, then the

servo control valve (WP 0250

00) if needed.

b. If boom will extend and retract

normally, but not lift or lower,

replace the main control valve

assembly (WP 0249 00).

0007 00-74