TM 10-3930-675-24-1

TROUBLESHOOTING PROCEDURES (NON-ERROR CODE) - CONTINUED

0007 00

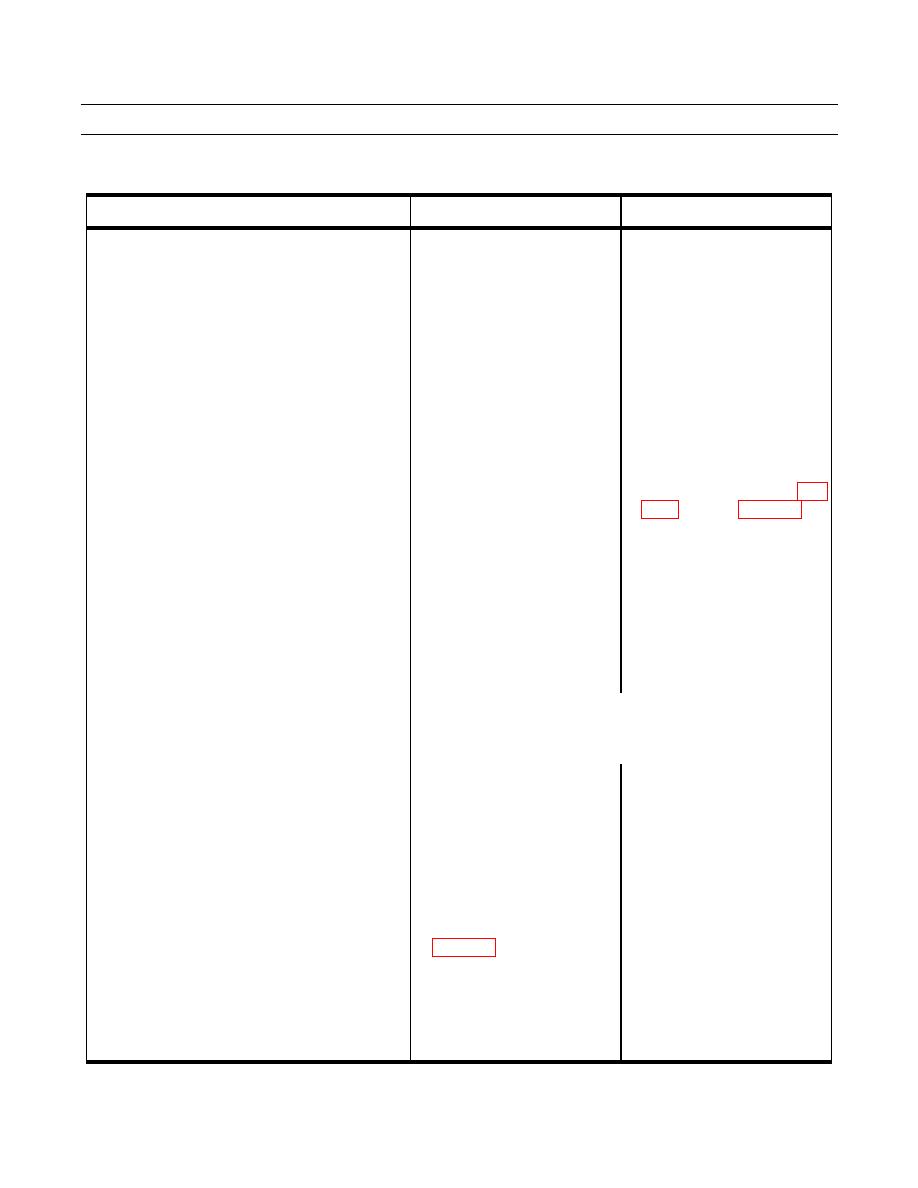

Table 7. Boom System Troubleshooting Procedures (Non-Error Code) - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. Boom Will Not Extend or Retract Properly -

b. If boom will extend and retract

Continued.

normally, but not lift or lower,

replace the main control valve

assembly (WP 0249 00).

c. If test point 8 pressure is not

normal, replace boom and

brake system hydraulic pump

(WP 0246 00).

3. Boom Folding Cylinders Not Working.

1. Check operation of

all a. If no tophandler functions

tophandler functions.

operate, check tophandler

pump pressure at test point no.

11 (WP 0188 00).

b. Troubleshooting pump control

circuit (611 solenoid) (WP

50).

c. Replace

steering

and

tophandler pump assembly

(WP 0242 00).

2. Check clearance of cab Move cab closer to the frame.

proximity switch (7210) Adjust cab or proximity switch

between cab and frame. Move (7210) to correct clearance.

the cab to the transport position

(TM 10-3930-675-10).

NOTE

DO NOT adjust proximity switch (7210) beyond end of

enclosure.

3. Inspect boom folding control Replace damaged or leaking

valve for damage and signs of boom folding control valve(s)

leakage. Pull back on the bogie (WP 0172 00).

wheel lever and check if bogie

wheel will lift off the locking

collar.

4. Check cab proximity switch a. Replace

damaged

or

(7210) and solenoid valve

inoperative proximity switch

(6043) operation and wiring

(WP 0076 00).

(WP 0048 00-30).

b. Replace damaged or faulty

solenoid valve (WP 0171 00).

0007 00-76