TM 5-3810-306-34

e. Reinstall valves in their corresponding bores.

ASSEMBLY:

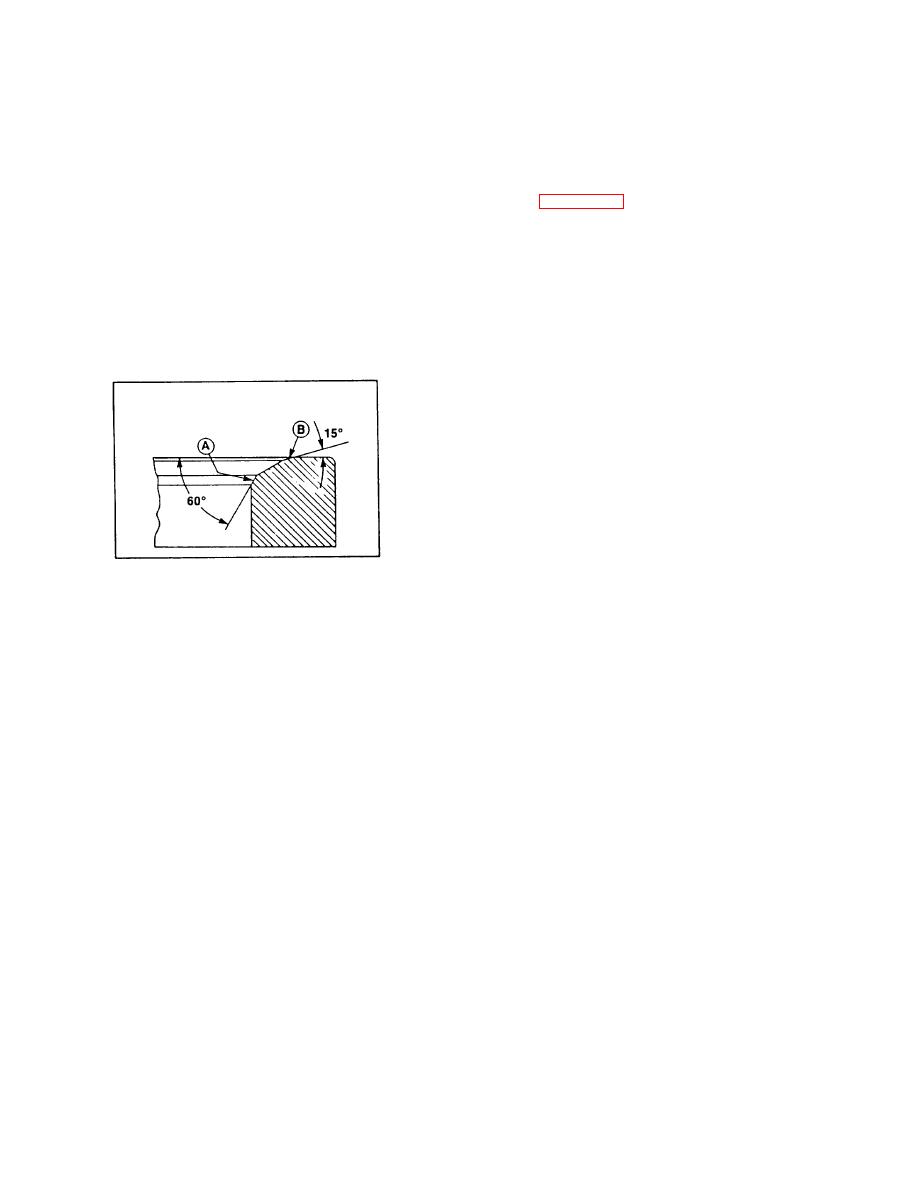

The valve seat should seat in the center of the

valve face.

1. IF REMOVED, INSTALL NEW VALVE GUIDES (11).

f.

Measure the valve seat width indicated by the

a. Fabricate two spacers (Items 12 and 13,

lapped surface. Minimum seat width .060 in.

(1.5 mm). Maximum seat width .080 in. (2.0

new valve guides (11).

mm).

g. If valve seat width limits are not met or the seat

NOTE

is not centered, grind area (A) with a 60 degree

stone and area (B) with a 15 degree stone to

Valve guide depth is very important

center the seat on the valve face and obtain the

and care should be taken to machine

valve seat width limits.

spacers to correct dimensions.

b. Using universal valve guide driver, start guides

(11) into head. Make sure guides start straight.

c.

Install the proper spacer over guide. If required,

install a flat washer on driver o contact spacer.

d. Drive guide (11) in, until driver contacts spacer.

e. Using a .3750 in. (9.525 mm) reamer, ream

valve guides (11) with no lubricant and in one

direction only.

NOTE

h. After reaching limits above, coat each valve face

with "Dykem Steel Blue" and allow to dry.

Damage to valve guide can result

from pulling reamer back through

i.

Apply a coat of valve lapping compound to each

guide.

valve and lap the valve to its corresponding seat.

f.

Lubricate reamer with clean engine oil and run

j.

Remove valves and clean compound from valve

through a second time in one direction only.

faces and seats.

NOTE

Keep valves in a labeled rack to

prevent mixing.

4-14