TM 5-3810-306-34

WARNING

Keep body clear of test spray. Fluid

can be injected into bloodstream

causing

blood

poisoning

and

possible death.

a. Open valve on fuel injector tester and

operate lever at one stoke per second.

b. Spray should start at 205 bar (2973 psi).

c. Check for well atomized spray pattern.

2. FUEL INJECTOR LEAKAGE TEST.

a. Open valve on fuel injector tester and

operate lever to hold pressure 20 bar (290

psi) below opening pressure.

b. No drops should fall from fuel injector tip

within 10 seconds.

INSTALLATION:

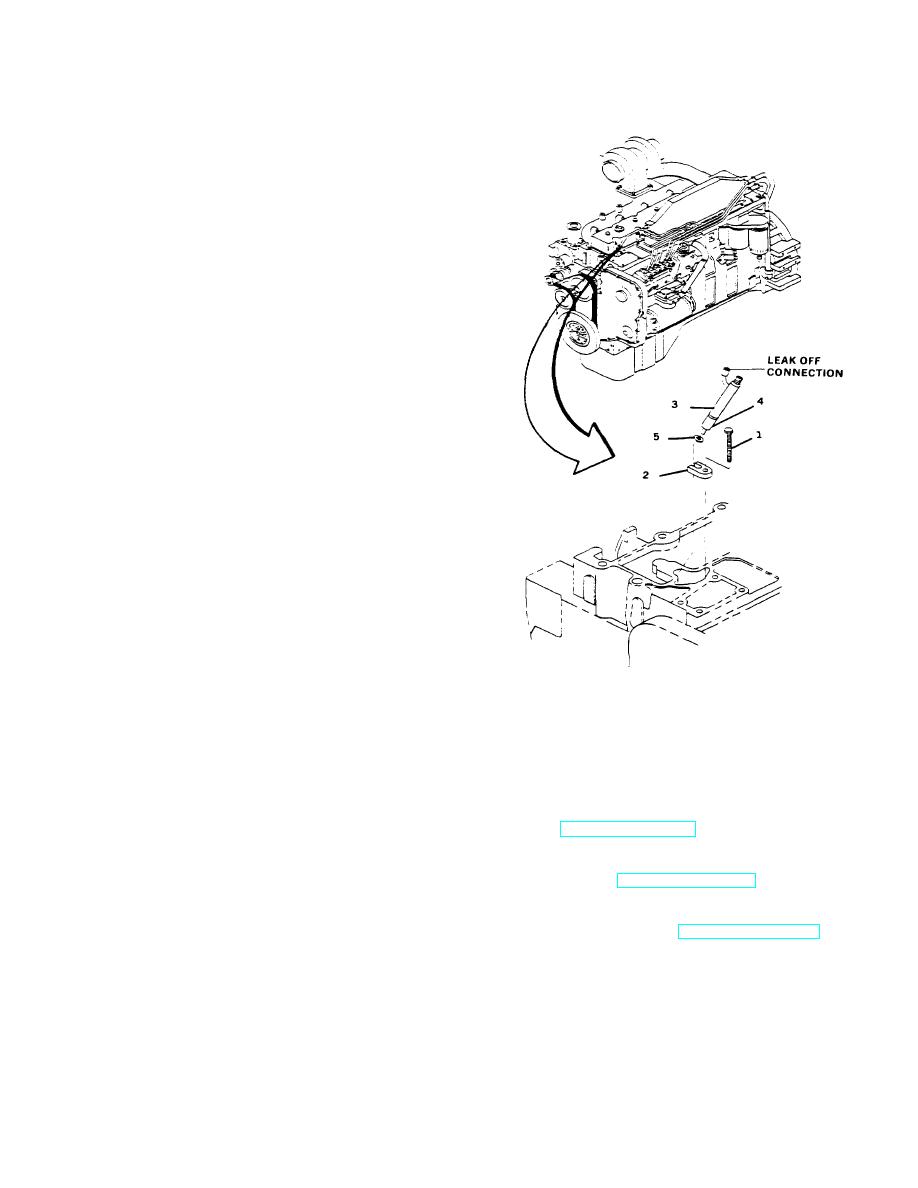

1. INSTALL FUEL INJECTOR(S).

a. Lubricate injectors with clean engine oil

and install new sealing sleeves (4) on

injectors (3).

b. Lubricate sealing lips of sleeve (4) with

anti-seize compound.

d. Install injector assembly into injector bore.

Injector leak-off connection must be

NOTE

toward valve cover.

A light coat of clean 15W40 engine oil

e. Tighten holddown capscrew (1). Torque

between the washer (5) and injector

to 18 ft-lbs (24 Nm).

(3) can help to keep the washer from

falling during installation.

2. INSTALL FUEL INJECTION LINES.

(REFER

TO TM 5-3810-306-20.)

c. Assemble injector (3), sealing sleeve (4),

new copper sealing washer (5) and

3. INSTALL TURBOCHARGER AFTERCOOLER.

holddown clamp (2). Use only one washer

(REFER TO TM 5-3810-306-20.)

(5).

4. CONNECT NEGATIVE BATTERY CABLE AT

SHUNT. (REFER TO TM 5-3810-306-20.)

END OF TASK

5-3