TM 5-3810-306-34

2. INSPECT ALL PARTS FOR DAMAGE AND

REPLACE AS NECESSARY.

a. Apply 70 lbs psi (483 kPa) air pressure to

core (10) and check for leaks with element

in water tank.

INSTALLATION:

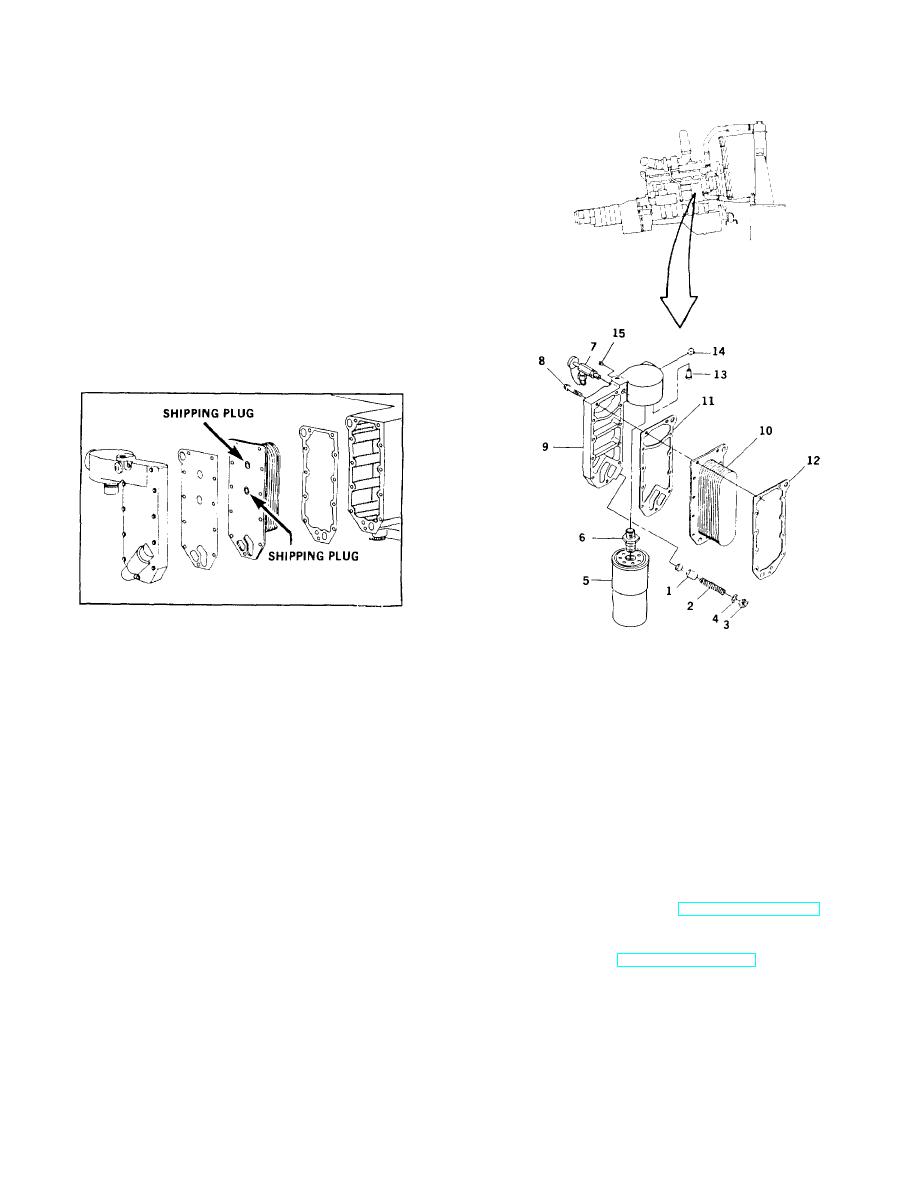

NOTE

If a new oil cooler core is to

be installed.

Be sure to

remove shipping plugs from

new core.

1. CLEAN ALL SEALING SURFACES.

e. Install oil sampling valve (7).

2. INSTALL OIL COOLER ASSEMBLY.

f. Install turbocharger oil supply line.

a. If removed, install plugs (14) and (15).

g. Install regulator valve (1) into bore and

b. Install new gaskets (11) and (12), core

ensure it moves freely.

(10) and cover (9). Secure with eleven

capscrews (8).

h. Install spring (2) and secure with new

copper washer (4) and retainer plug (3).

c. Install bypass valve (13).

3. SERVICE RADIATOR. (REFER TO LO 53810-

CAUTION

306-12.)

Mechanical

overtightening

may

4. CONNECT NEGATIVE BATTERY CABLE AT

distort the threads or damage the

SHUNT. (REFER TO TM 5-3810-306-20.)

filter element (5) seal.

5. START ENGINE AND INSPECT FOR LEAKS.

d. Install new oil filter element (5). Follow

(REFER TO TM 5-3810-306-10.)

manufacturer's instruction for tightening.

END OF TASK

4-63/4-64 Blank