TM 5-3810-306-34

3. INSTALL CRANKSHAFT (11) AND SUPPORT (7).

a. Use clean engine oil to lubricate bore in support

(7). Install support (7) over crankshaft.

b. Use clean engine oil to lubricate thrust bearing

(6) and install it with part number side out (or

grooved side facing in).

c.

Use clean engine oil to lubricate spacer (5) and

gear (4). Install spacer (5) and using press,

install gear (4) until spacer contacts thrust

bearing. Install capscrew (2) with washer (3).

Torque capscrew (2) to 93 ft-lbs (124 Nm).

d. Measure distance between support (7) and

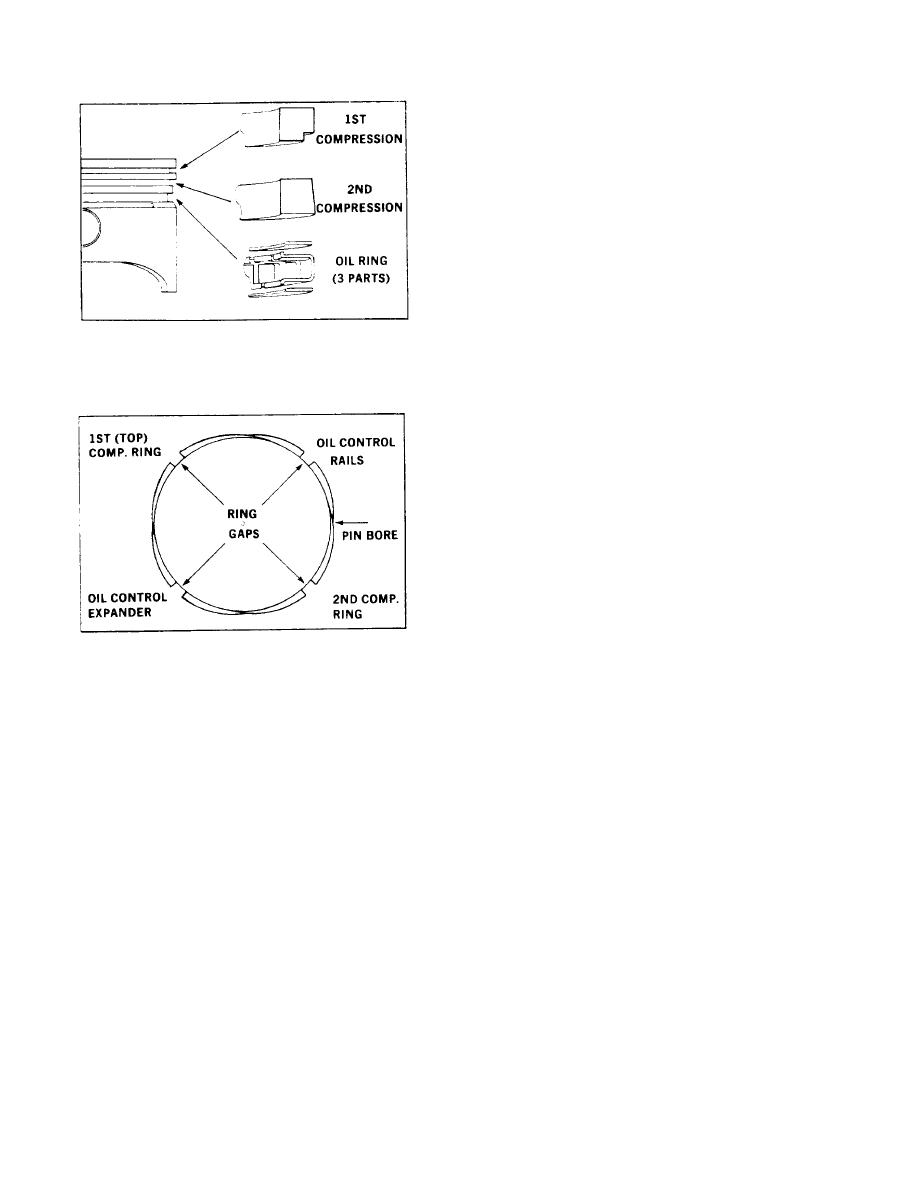

e. Position piston oil ring and piston ring gaps so

crankshaft (11) mating surfaces.

This

that they are not over piston pin bore.

measurement should be:

Min = .004 in. (.102 mm)

Max = .009 in. (.229 mm)

Worn = .012 in. (.305 mm)

e. Install new gasket (10) on support (7).

f.

Position piston at 90 before or after top-dead-

center and install crankshaft (11) with support (7)

into crankcase (13).

g. Install captive washer capscrews (15).

h. Install captive washer capscrews (8) and

washers (9). Torque capscrews (8) and (15) to

30-35 ft-lbs (41-47 Nm).

2. INSTALL PISTON (21) AND CONNECTING ROD

(17).

a. Use clean engine oil to lubricate piston rings,

compress piston rings and install piston (21) and

connecting rod (17).

b. If removed, install pipe plug (12) and tighten 3-6

ft-lb (4-8 Nm).

c.

If removed, using press, install adapter (57) on

crankshaft (11).

9-14