TM 5-3810-306-34

CHECKS a AND b

CHECK c

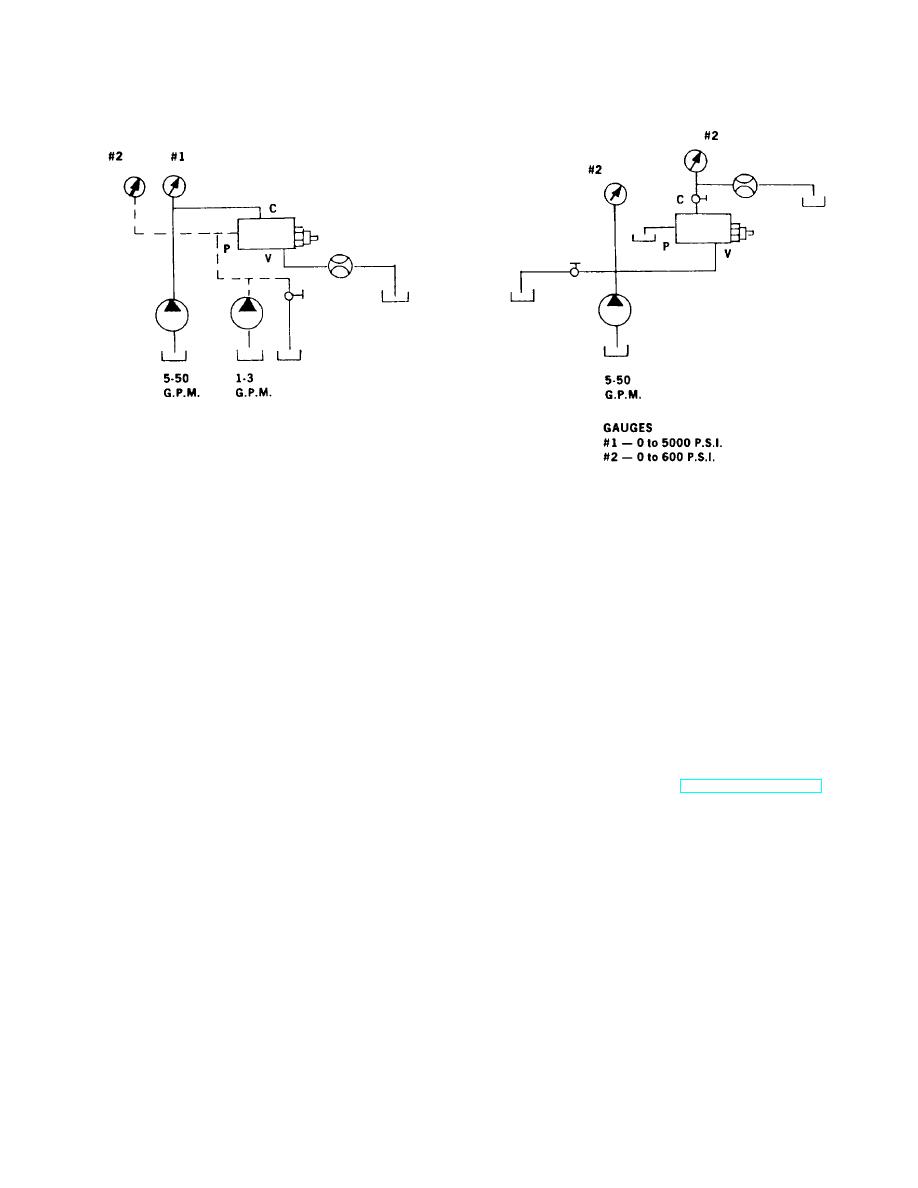

BENCH CHECK SET UP

a. Pilot pressure adjustment.

2) Apply 20 psi into all ports simultaneously and

observe for external leakage. No leakage

1) Induce 2000 psi into "cylinder" port and 375

allowed.

psi into "pilot pressure" port. Adjust valve

with adjusting bolt to allow 1/4 GPM flow

c.

Free flow check test.

10% out of "valve" port.

1) Pressurize "valve" port to check function of

2) Vary pilot pressure to open and close valve

free flow check. Check valve to crack at 25

several times. Recheck valve at 375 psi

psi.

pilot pressure (and 2000 psi induced into

"cylinder" port) to verify proper adjustment.

2) Induce 25 GPM flow into "valve" port.

Pressure drop through valve not to exceed

b. Leakage test.

70 psi.

1) Induce 2500 psi into "cylinder" port and

4. INSTALL LIFT CYLINDER OVER CENTER VALVE

observe "valve" and "pilot pressure" ports for

ASSEMBLY. (REFER TO TM 5-3810-306-20.)

leakage (5 drops per min. allowed after 2

min.).

END OF TASK

13-106