TM 5-3810-306-34

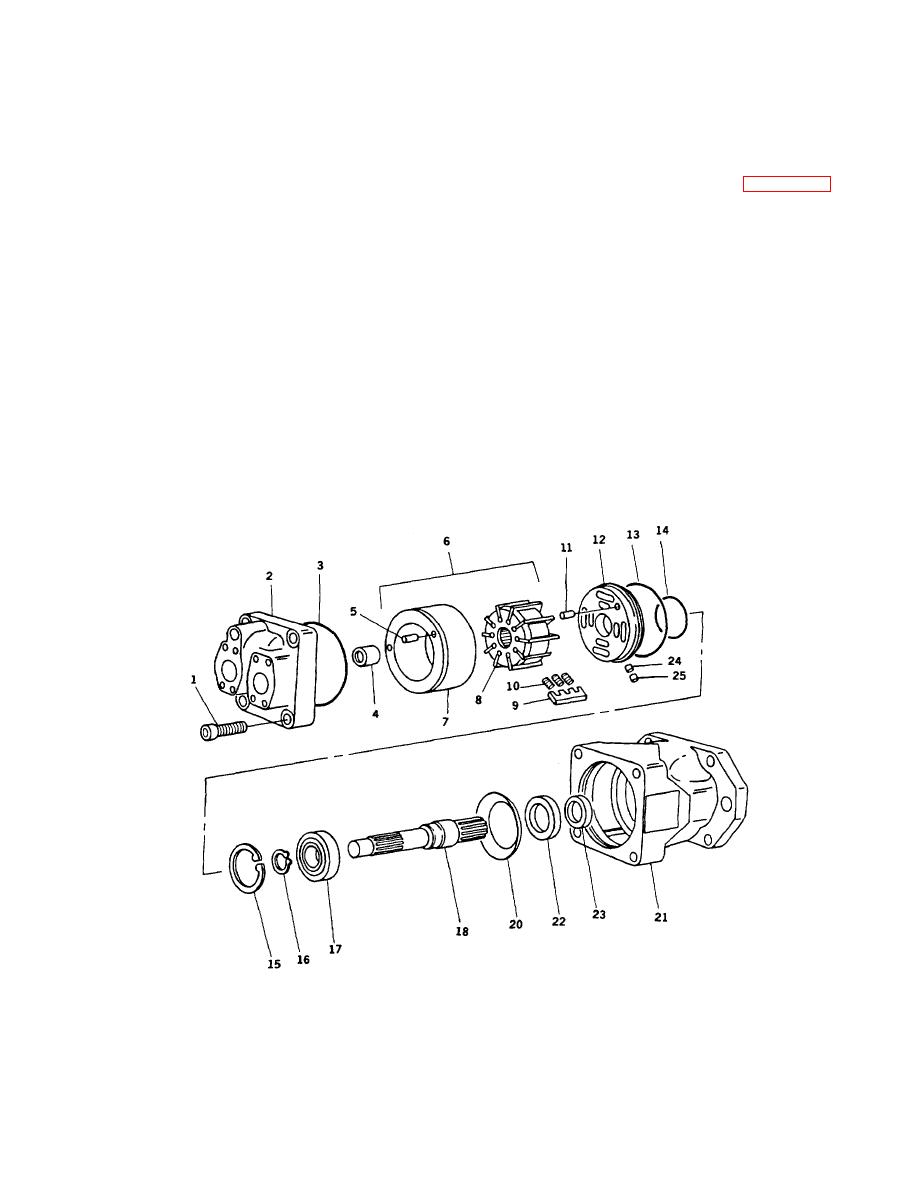

3. INSTALL SHAFT SEAL (22) AND BEARING (17).

ASSEMBLY:

a. Turn body (21) over with large open end facing

NOTE

up.

Tools are required to properly install

b. Use shaft seal driver (Item 1, Appendix C) and

the shaft oil seal. A driver must be

drive shaft seal (22) into body (21) until it seats

used to install the shaft seal. A

in counterbore.

protective cone must be used over

the shaft end to prevent damage to

NOTE

the shaft seal when installing the

shaft.

Ensure open side of seal is toward

inside of the body.

1. SOAK SEALS AND

IN

CLEAN

HYDRAULIC OIL.

c.

Press bearing (17) on shaft (18) to shoulder and

install external snap ring (16).

2. INSTALL WIPER SEAL (23).

d. Ensure ring is seated in snap ring groove.

a. Position body (21) on a clean, flat surface with

small open end up.

4. INSTALL SHAFT (18).

b. Press new wiper seal (23) in 2-1/16 inch hole.

a. Apply lubricating fluid to inside of shaft seal (22)

Wiper seal must be flush with bottom of

and wiper seal (23).

counterbore.

15-57