TM 55-8145-202-14

5-12.

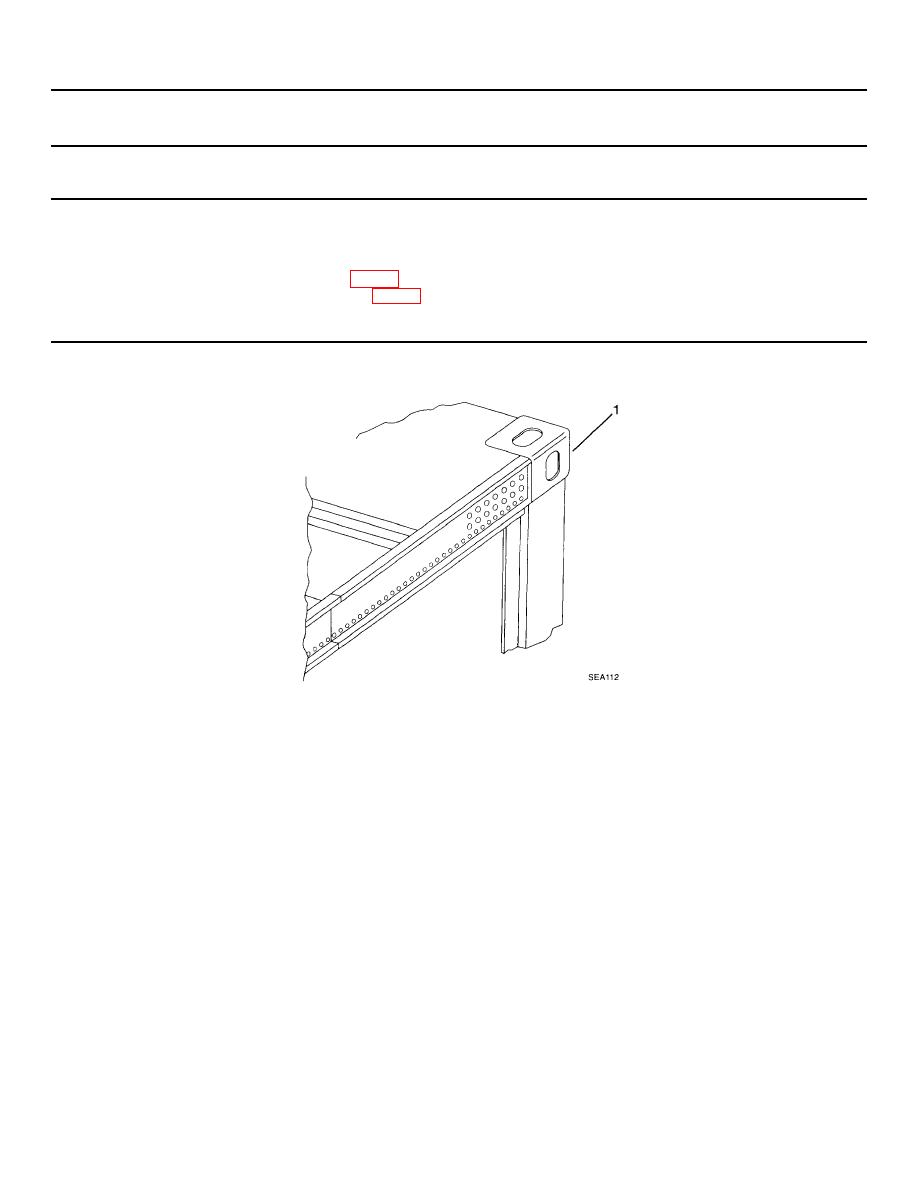

CORNER FITTINGS.

This task covers:

a. Removal

b. Installation

INITIAL SET-UP:

Tools:

Equipment Condition:

General Mechanics Tool Kit (Item 1, App B)

Refrigeration unit shutdown

Welding Shop, Trailer Mounted (Item 3, App B)

(TM 9-4110-258-13)

Generator set shutdown (TM 5-6115-585-12/34)

a.

Removal.

Damaged corner fittings must be replaced.

(1) Cut out the damaged fitting (1) along existing welds.

(2) Carefully grind all existing welds back to base metal.

b.

Installation.

(1) To ensure complete penetration of welds, edges of metal next to fittings should be ground to a 45

bevel.

NOTE

To ensure proper engagement of container handling devices, it is important that the distance

between hole centers be the same as it was with the old fitting, and that the fitting is properly

positioned horizontally.

(2) Position corner fitting (1) with gaps of no more than 5/64 in (2 mm) before welding.

(3) When possible, connections to the fitting should be fully welded on both sides of the joint. Welds must

be uniform, free of scale, pin and blow holes, and with full penetration. All welds to corner fittings must

be made with low hydrogen welding rods.

5-15