TM 55-8145-202-14

5-14.

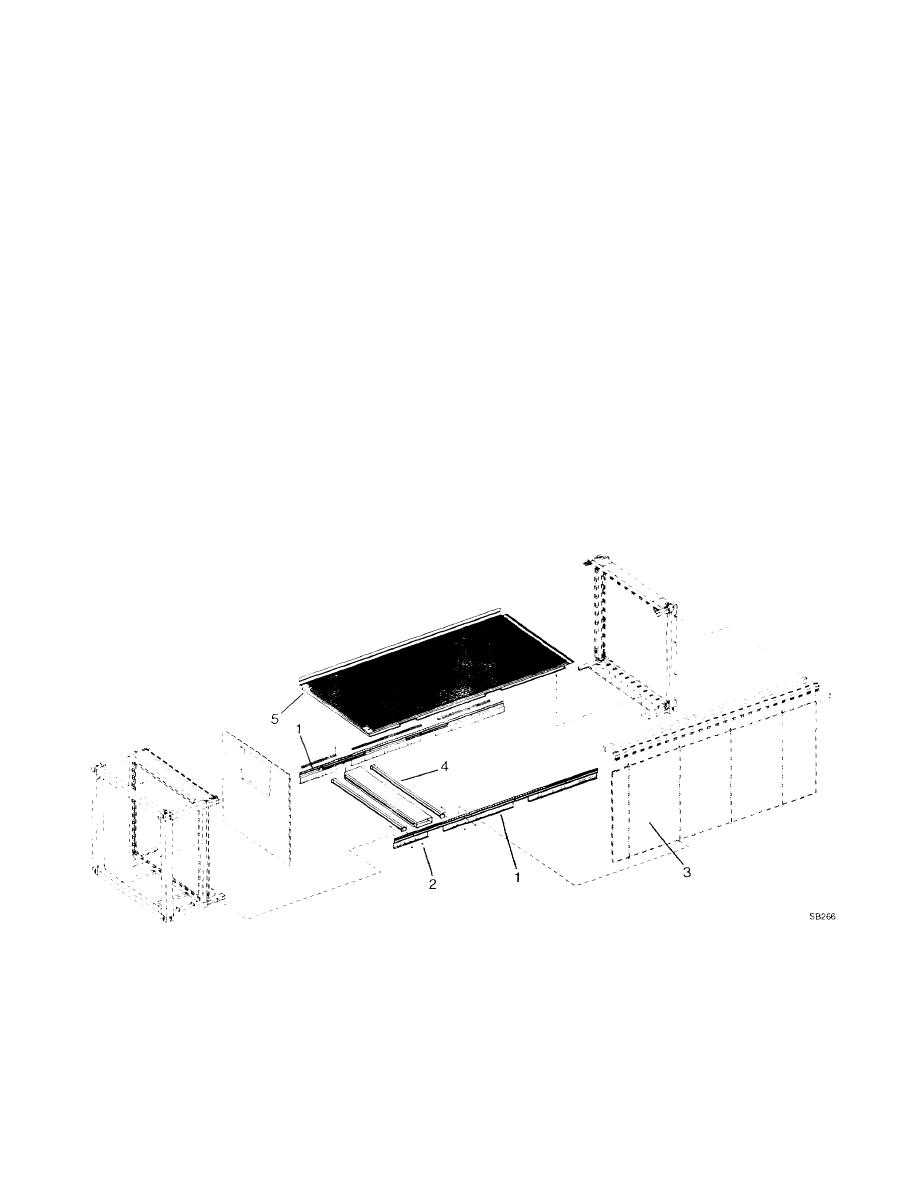

BOTTOM RAILS - Continued

c.

Inserting.

Damage that cannot be repaired by straightening may be repaired by replacing the damaged area with

an insert. The following limitations apply:

Inserts can be any profile that does not extend through the entire cross section of the rail.

Inserts must be a minimum of 6 in (150 mm) in length.

Inserts must be fitted flush with the original material.

If an insert would end within 6 in (150 mm, of another vertical rail weld, it must be

extended to that weld or to the fitting.

If an insert in a bottom side rail would end within 12 in (300 mm) of a corner fitting, it

must be extended to the fitting.

Insets must have the same cross sectional profile as the original rail.

(1)

Determine the length of rail (1) to be removed. Mark where the area is to be cut.

(2)

Remove rivets (2) securing the bottom rail (1) to side panel (3) and crossmembers (4).

Remove any foam, lining and/or other parts which block access to the repair area.

(3)

Separate side panel (3) from bottom rail (1) with wedges no more than 5/32 in (4 mm) thick.

(4)

Using a disc grinder, cut out the damaged area. Grind all cut areas smooth and clean.

(5)

Straighten the remaining rail edges if bent. Clean and smooth all cut edges with a disc grinder.

5-20