TM 55-8145-202-14

5-18.

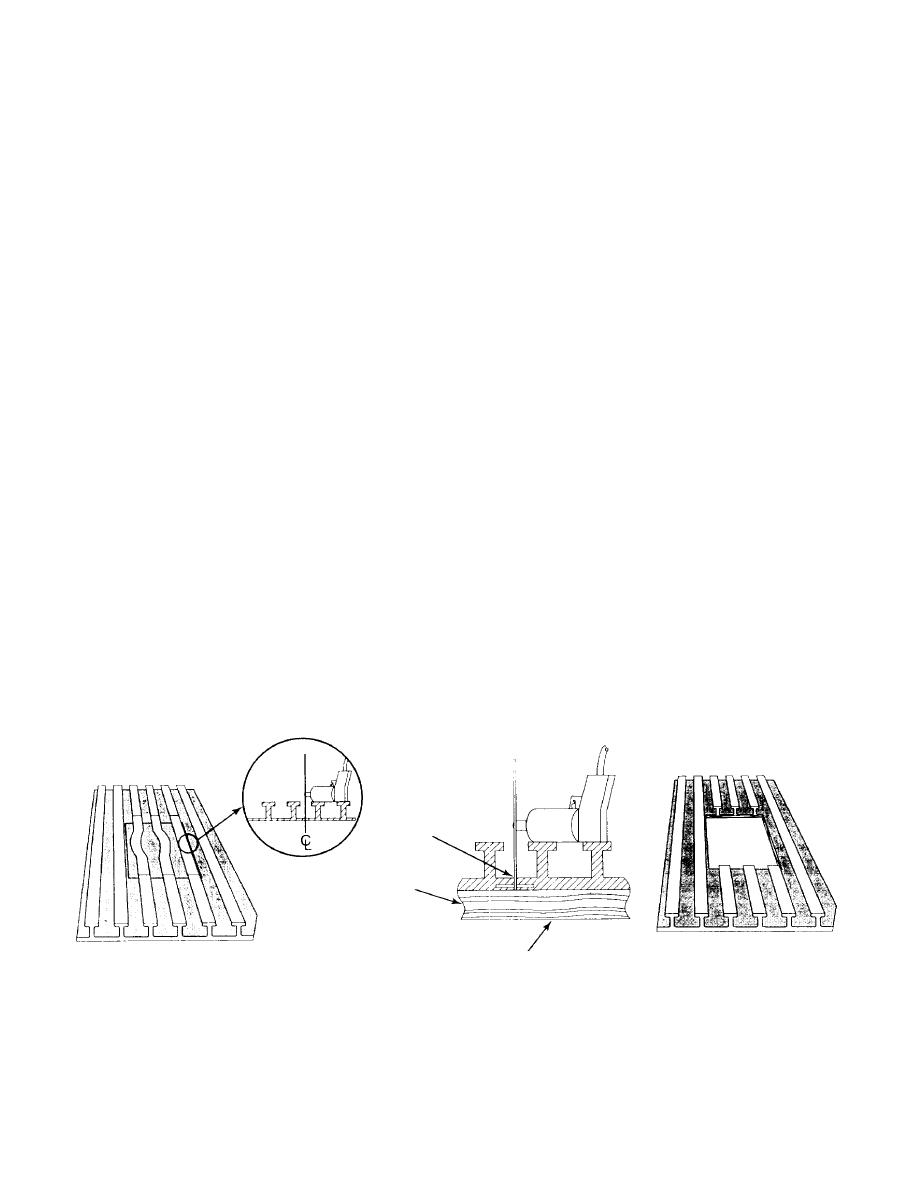

FLOOR - Continued

(3)

Examine insulation for damage and moisture.

(4)

Grind the cut edges smooth and square, and remove any contamination.

NOTE

Weld-backing strips must be used to protect the foam insulation.

(5)

Prepare aluminum strips 5/64" (2 mm) thick and 2" (50 mm) wide.

(a)

Place the strips between the foam and the original floor on all four sides of the cut.

(b)

Allow 1" (25 mm) of the strips to show all around.

(6)

Prepare a replacement " " section from material of the same dimensions, profile, and

T

specifications as the original floor. Allow a maximum clearance of 5/64" (2 mm).

(7)

Apply adhesive primer to the back of the replacement section.

(8)

Apply polyurethane adhesive to the face of the foam, and insert the new replacement section.

(a)

It may be necessary to apply weight to the replacement section in order

to position the section flush with the original floor.

(b)

Use a straight edge to verify flush fit.

(9)

Tack weld the section, notify Direct Support Maintenance.

(10)

Check for correct alignment.

(11)

Continuously weld into position. Verify that welds are continuous with no pin holes.

(12)

Grind smooth all welds made on the top face of " " profiles.

T

SET TO

MINIMUM

DEPTH

SUFFICIENT TO

CUT SECTION

FREE

FOAM

SUBFLOOR (UNDERFLOOR PANEL)

5-32