TM 10-3930-675-10-2

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

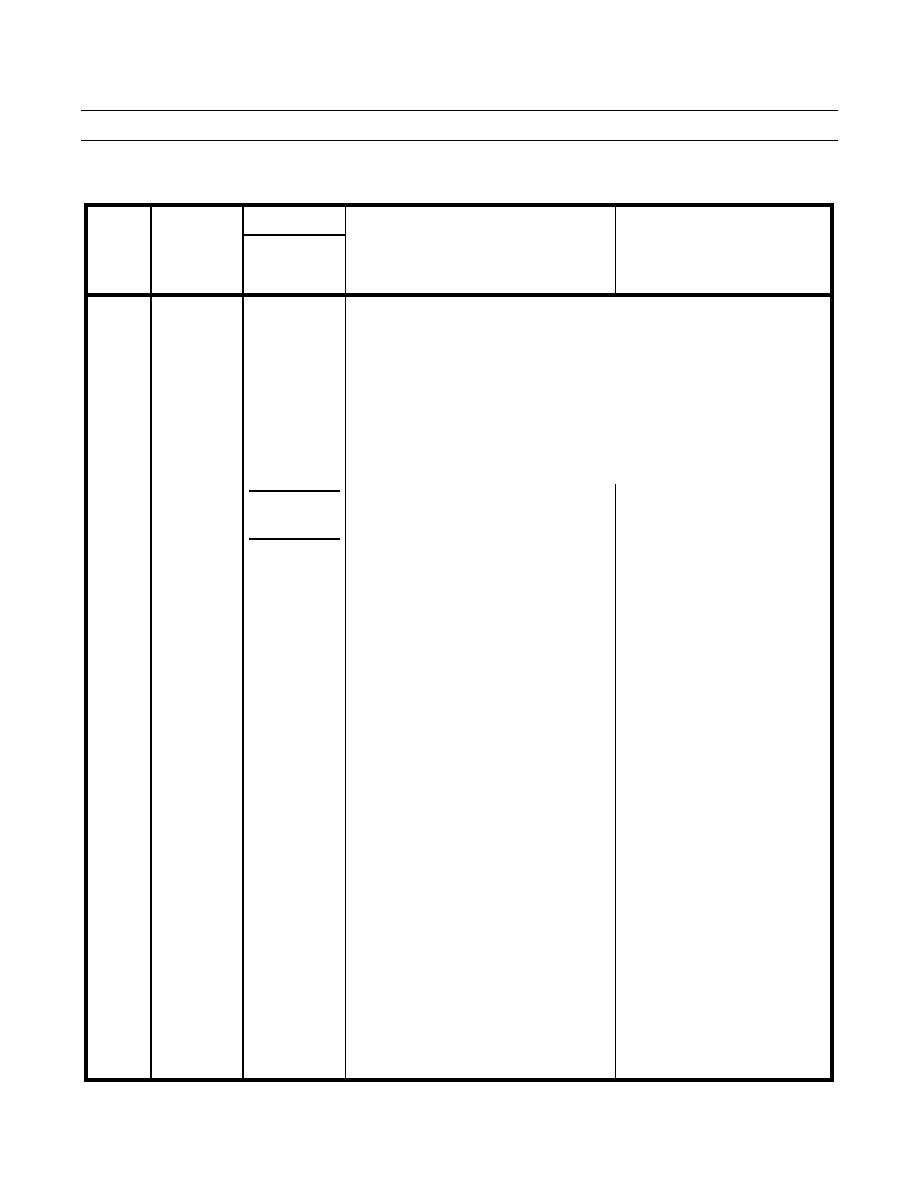

Table 1. Preventive Maintenance Checks and

Services (PMCS) for RTCH-RT 240V2.

LOCATION

ITEM TO

ITEM

CHECK/

NOT FULLY MISSION

NO.

INTERVAL

SERVICE

PROCEDURE

CAPABLE IF:

NOTE

Review all WARNINGs, CAUTIONs, and NOTEs before perform-

ing PMCS and operating the RTCH-RT 240V2.

Perform all PMCS checks if:

a. You are the assigned operator but have not operated the machine

since the last weekly checks.

b. You are operating the RTCH for the first time.

At 100 hours of operation, notify Organizational Maintenance to

perform 100-hour initial checks and services.

FRONT AND

LEFT SIDE

1

Before

Overall View

a. Check under RTCH for evidence of fluid Class III oil, coolant, or hydraulic

leakages such as fuel, oil, coolant, or leaks are evident. Any fuel leaks

hydraulic fluid.

are evident.

b. Visually check that tread is visible and No tread is visible, if there are

for damaged tires. Check for missing gages below the tread cavity

or signs of loose lug nuts.

surface depth, there are cuts in

sidewall deep enough to expose

the steel cord, or there are missing

lug nuts.

2

Before

Hydraulic

Check hydraulic cylinders behind

Class III leaks are evident.

staircase, hydraulic hoses, lines, and

Cylinders

fittings for damage and leaks.

3

Before

Remote

a. Open compartment door and visually Class III leaks are evident.

Hydraulic

check hydraulic controls, valves, and

Control Com-

lines for signs of leakage.

partment

b. Check compartment door, door hinge,

and retaining latch for damage.

4

Before

Cab Exterior

a. Check for damage to cab door, steps,

and handrail.

b. Check for damage to cab glass (front, Damage that would interfere

top, sides, and rear), windshield wiper with visibility or impair safe

blades, and arms.

operation is evident.

c. Check for damage to the rear of cab, Class III leaks are evident.

windshield washer reservoir, horn, air

conditioning system components, and

hydraulic lines and cylinders.