TM 10-3930-675-20-2

0167 00-6

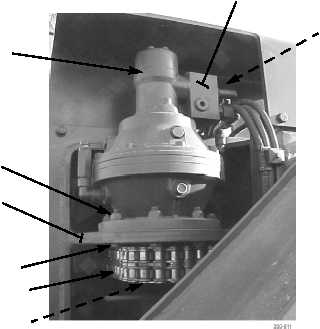

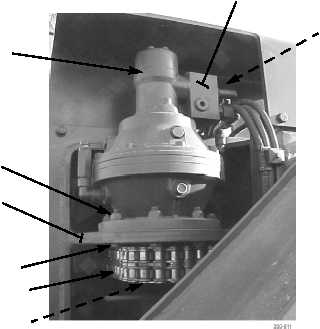

TOPHANDLER HYDRAULIC SPREADER MOTOR REPLACEMENT - CONTINUED

0167 00

INSTALLATION

WARNING

•

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during

procedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep

clear of heavy parts supported only by lifting device. Failure to follow this warning may result in death

or injury to personnel.

•

Spreader motor weighs approximately 150 lb (68 kg). Lifting device must have sufficient capacity to

lift motor. Failure to follow this warning may result in injury to personnel.

NOTE

Ensure spreader motor is oriented to allow connection of hydraulic manifold.

1.

Using suitable lifting device, nylon sling, and with assistance, install spreader motor (10) on mounting weldment (17).

NOTE

Ensure screws are installed from bottom up as noted in removal.

2.

Install ten screws (16), washers (18), and nuts (19) to secure spreader motor (10). Tighten screws in an even pattern in

accordance with Torque Limits (WP 0198 00).

NOTE

Ensure o-rings are lubricated with lubricating oil prior to installation.

3.

Position hydraulic manifold (11) with hoses and new o-rings (12) to spreader motor (10) and secure with four socket

head screws (13).

4.

Position chain (15) on drive sprocket (14).

14

15

16

17

18,19

10

11,12

13