TM 10-3930-675-24-1

TROUBLESHOOTING INTRODUCTION - CONTINUED

0004 00

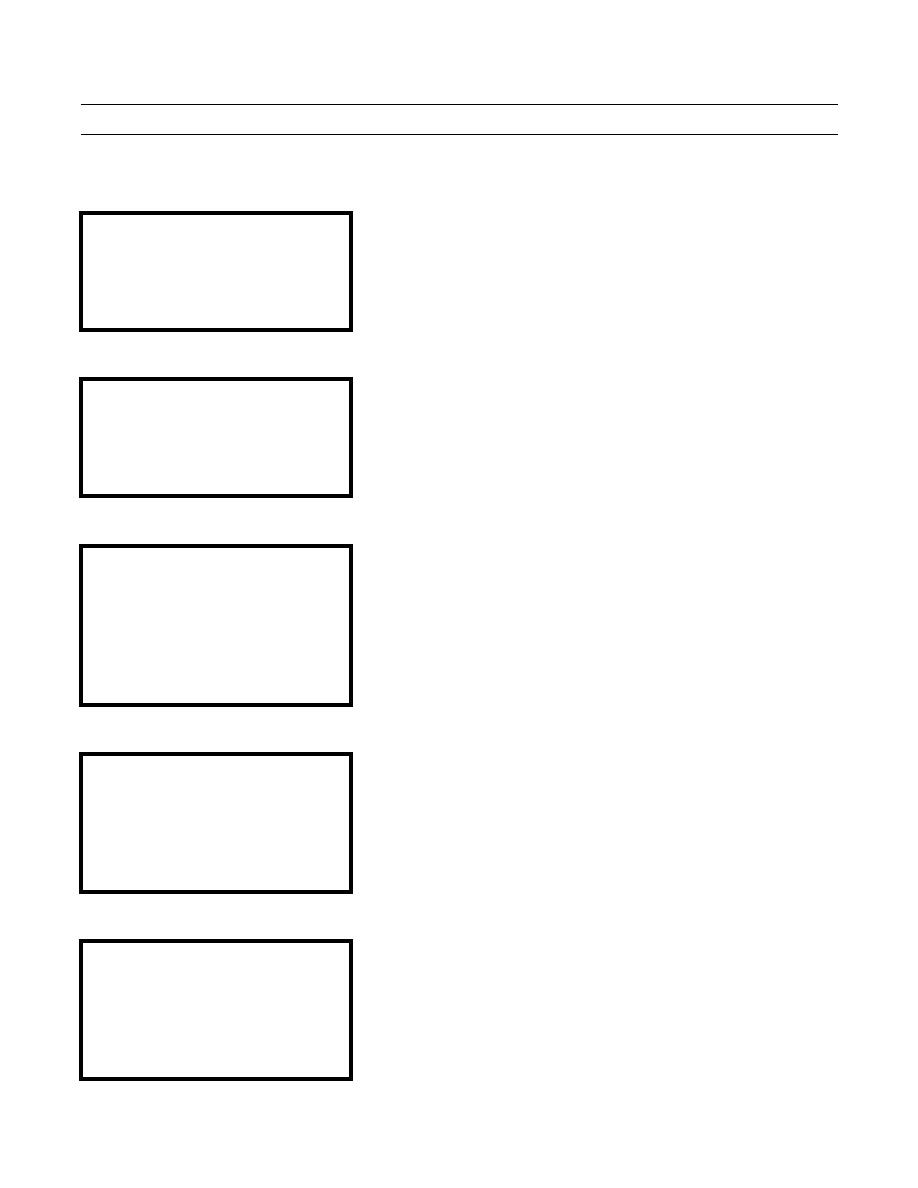

DIAG ATTACHMENT - CONTINUED

DIAG ATTACH

3(16)

Signals from alignment proximity switches to

ECU 791 connector 1.

ALIGNMENT

To test; activate manually or engage tophandler in

LE FRONT

0

RI FRONT 0

container.

LE REAR

0

RI REAR 0

1 = 24V signal, 0 = no signal

DIAG ATTACH

4(16)

Signals from twistlock proximity switches to ECU 791

connector 1.

TWISTLOCK

To test; override twistlocks.

LE UNL.

0

RI UNL.

0

1 = 24V signal, 0 = no signal

LE LOCK

0

RI LOCK

0

DIAG ATTACH

5(16)

Signals from rotation, damping, and forklift

attachment proximity switches to ECU 791 connector

ROTATION +/- 45

1

1.

DAMPING 20/40

0

Rotational/work light lockout; 3998R/7364 only.

ATTACHMENT SIG 1

1

Damping signal occurs during spreading extremes,

ATTACHMENT SIG 2

1

Attachment signal normally on until the forklift kit is

installed. 1 = 24V signal, 0 = no signal.

DIAG ATTACH

6(16)

Signals from ECU 791 connector 2 to twistlock valve

solenoids.

TW-LOCK OUTPUT

INPUT

Voltage (24V) to solenoids and actual amperage

UNLOCKED 0.00V

0mA

through solenoid coils when twistlock function is

LOCKED

0.00V

0mA

activated.

DIAG ATTACH

7(16)

Signals from ECU 791 connector 2 from the side shift

SIDE SH. OUTPUT

INPUT

valve solenoids.

LEFT

0mA

0mA

Output = Target value, Input = Actual value

RIGHT

0mA

0mA

Activating side shift function; the target value appears.

The actual amperage will rise to closely match the

target value.

0004 00-12