TM 5-3810-306-34

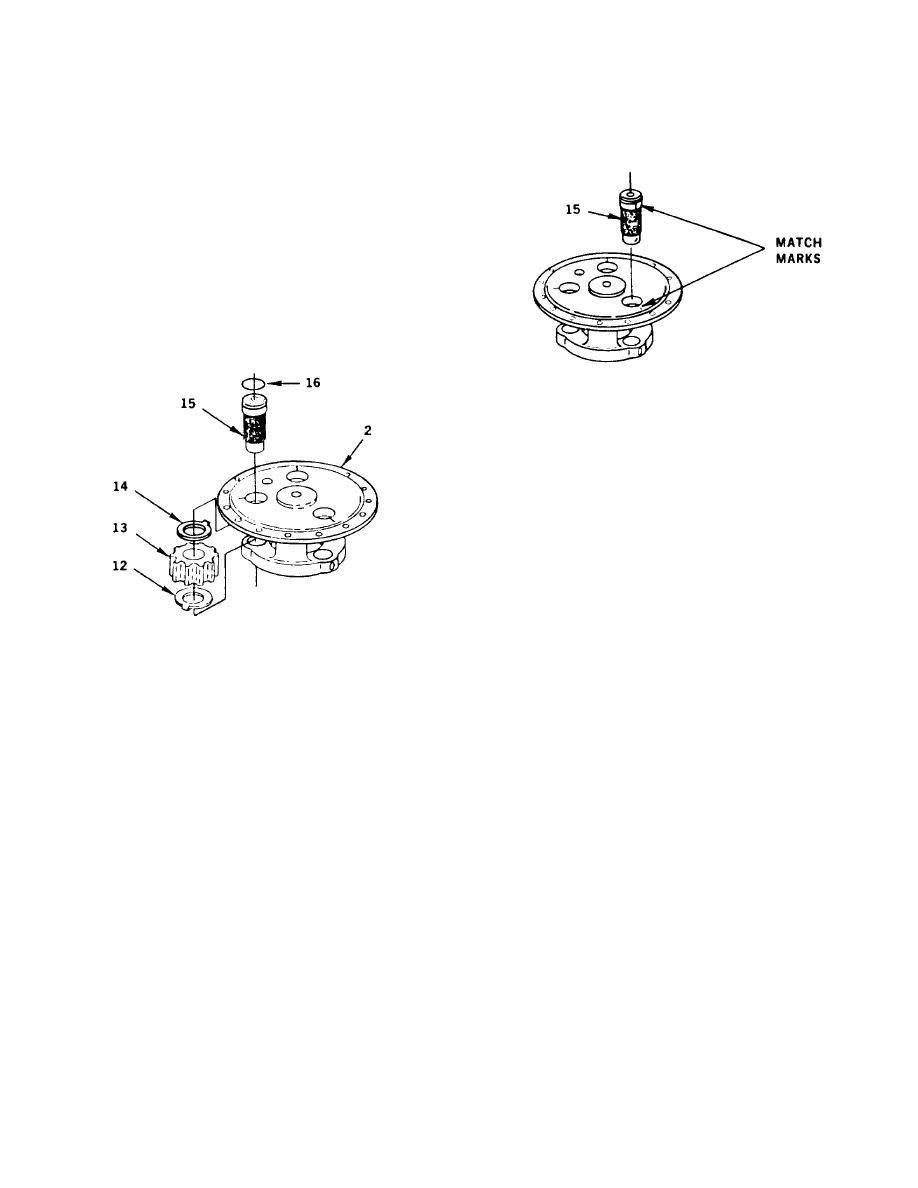

g. On axle models with one-piece integral

CAUTION

spider and cover align match-mark on

large diameter of shaft with match-mark

Chamfers on large bores must be

on spider.

smooth. Use emery cloth to remove

surface blemishes. Failure to follow

this caution could result in damage to

shaft (15) and preformed packing

(16).

b. Install new preformed packing (16) on

each shaft (15).

Ensure preformed

packing (16) is not twisted.

c. Place spider (2) in press with the flange

side up. Block up as required.

NOTE

These match-marks provide proper

alignment of the set screw hole in the

small end of the shaft and the tapped

set screw hole in the spider boss.

h. Apply film of non-hardening sealant

(Permatex 51 or equivalent) to preformed

packing (16) and large end of shaft.

CAUTION

Do not strike shafts (15) directly with

a steel hammer. Personal injury from

d. Install inner washer (12) with washer tab

chips or splinters may result.

engaged in spider indent and washer bore

aligned with spider bore.

NOTE

e. Coat bore of the spur gear (13) with a film

of MIL-L-2105 gear oil. Slide spur gear

If a press is not available use a brass

and outer flat washer (14) into spider.

drift and mallet to tap the shaft (15)

Align bores of parts and engage outer flat

through the spider and spur gear.

washer (14) tab in spider indent.

i. Being careful to keep shaft (15) aligned,

f. Install flat shaft (15) into spider and

press shaft into spider until shoulder of the

through the spur gear and flat washers by

shaft bottoms against inner flat washer

hand. The large end of the shaft will bind

(12).

in the spider bore due to an interference

fit.

8-58