TM 5-3810-306-34

g. Remove four nuts (30), lockwashers (31)

e. Position fan shroud (24) on oil cooler, align

and capscrews (32). Remove oil cooler

holes and insert fan mount (17) through

motor (8). Note position of fan mount (17)

holes, ensure spacers (19) are in place.

to oil cooler motor (8) for reassembly.

NOTE

INSTALLATION:

Tee fitting on motor (8) must face

1. INSTALL OIL COOLER MOTOR TO

OIL

boom nose.

COOLER.

f. Secure fan mount with nuts (16).

a. Position oil cooler motor on fan mount

bracket (17). Secure with capscrews (32),

g. Align holes in fan guard (23) with holes in

lockwashers (31) and nuts (30).

shroud (24) and secure with flatwashers

(22), lockwashers (21) and capscrews

b. Position fan guard (23) over motor shaft.

(20).

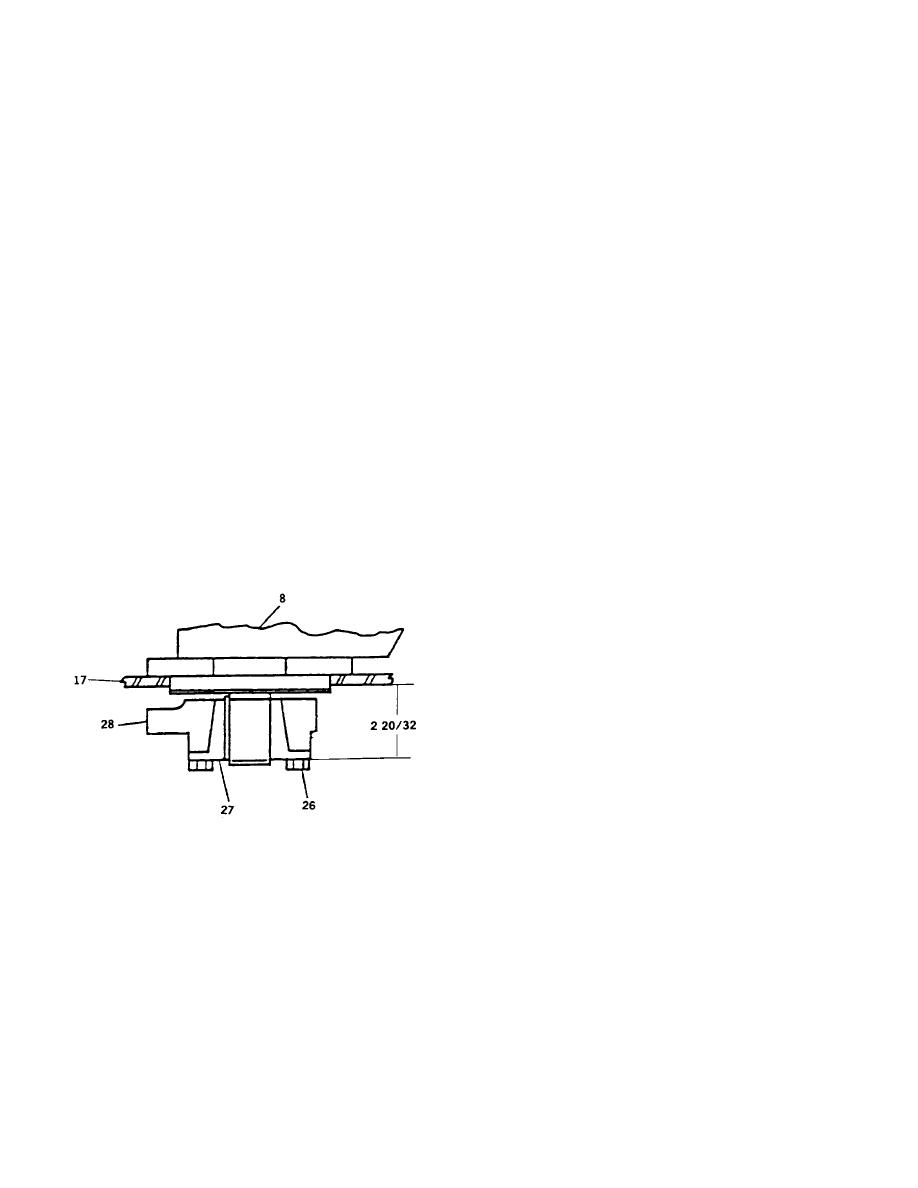

Position square key (29) and fan collar

(28) on motor shaft.

NOTE

c. Position key (33) and tapered bushing (27)

Ensure fan spins freely inside and is

on motor shaft. Ensure that measurement

centered between fan guard (23) and

from front of mounting plate (17) to front of

shroud (24) to eliminate any possible

tapered bushing (27) is 2 20/32 in. Install

oil cooler damage when motor starts.

and tighten cap screws (26) alternately to

Adjust by loosening and tightening

draw tapered bushing (27) and fan collar

nuts (16) on fan mount (17).

(28) together evenly. Torque cap screws

to 15 ft-lbs (20 Nm )

2. INSTALL OIL COOLER ON FRAME (13).

a. Position oil cooler assembly on frame and

secure with eight capscrews (15),

flatwashers (14), lockwashers (11) and

nuts (10). Ensure spacers (12) are in

place.

3. INSTALL OIL COOLER ASSEMBLY.

a. Using a suitable lifting device, position oil

cooler assembly on superstructure and

secure with four lockwashers (5) and

capscrews (4).

b. Install tagged hoses on oil cooler and oil

cooler motor.

d. Install fan (25) on fan collar (28) using

three socket head screws (34).

13-50