TM 5-3810-306-34

b. Remove four capscrews (12) from mounting

NOTE

flange (13). These motors are assembled using

Loctite on screws (12) to hold them in place.

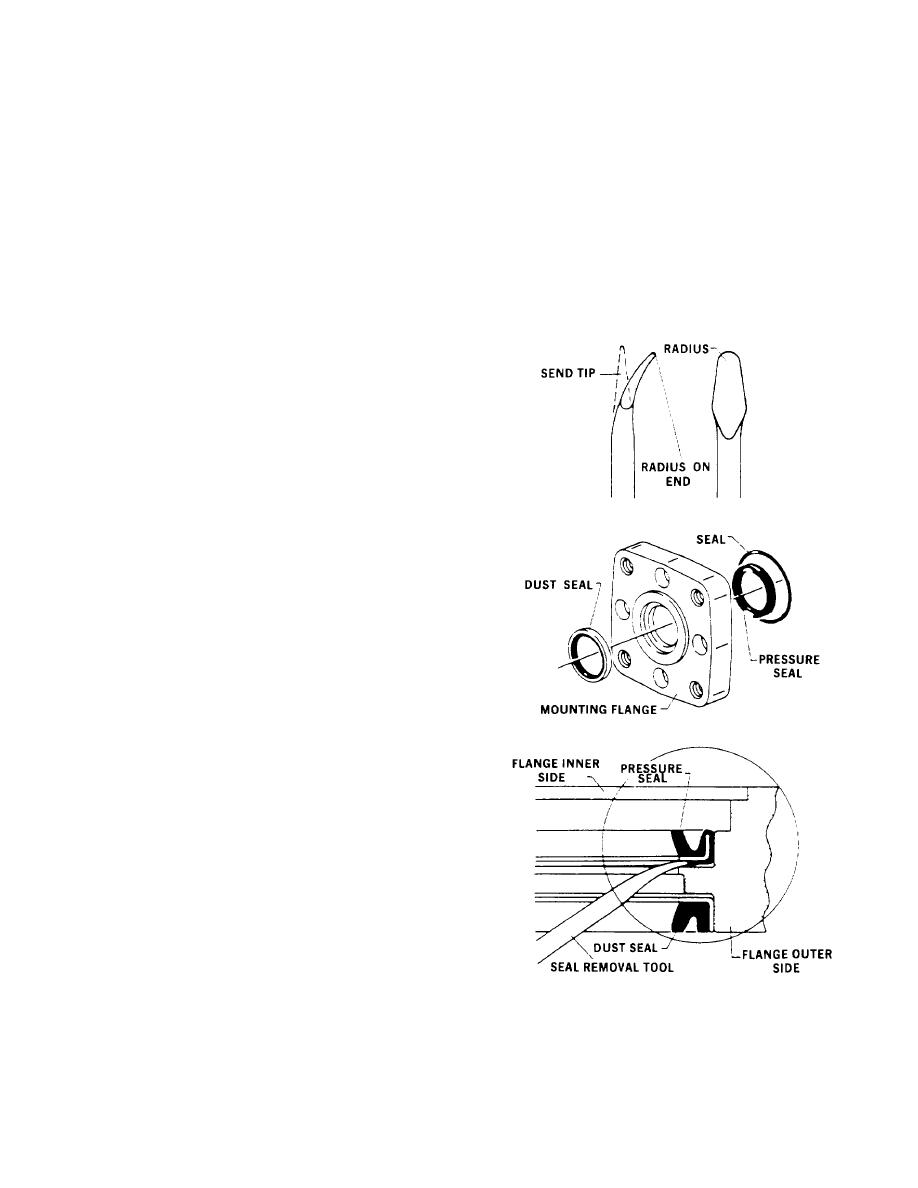

The dust seal (14), pressure

Screws (12) will require approximately 300 to

seal (15) and seal (16) will

400 in-lbs (33-44 Nm) of torque to break loose

come off with flange (11).

and approximately 100 in-lbs (11 Nm) of torque

to remove after they are broken loose. Do not

e. Use a seal remover tool, like the one shown to

use an impact wrench on screws held with

remove dust seal (14) and pressure seal (15).

Loctite, this may result in rounded heads or

Work from outer side to remove each seal.

broken sockets. If it requires more than 400 in

Work nose of tool between pressure seal (15)

lbs (44 Nm) to remove capscrews (12) proceed

and the flange (13). Pry seal partway. Remove

to step c otherwise proceed to step d.

tool and repeat at a point 180 degrees away.

Push seal (15) completely out of cavity.

CAUTION

Be careful not to overheat and

damage the motor.

c. Use a small flame propane torch to heat a small

area of housing (11) where the screw (12)

enters. Apply torque to capscrew (12) with a

socket wrench gradually as heat is applied for 8

to 10 seconds. As soon as screw breaks loose,

remove heat from housing, and continue turning

screw until it is completely removed.

d. Remove motor from vise and place it on a clean

flat surface. Carefully remove flange (13) from

the housing (11).

CAUTION

Use care not to scratch seal

cavity O.D. This could cause

leakage.

15-134