TM 5-3810-306-34

a. Check all mating surfaces, and replace any parts

having scratches or burrs that could cause

leakage or damage.

b. Check around chamfered area of shaft for burrs,

nicks, or sharp edges that can damage seals

when assembling flange. Nicks or burrs may be

removed with a hard, smooth stone (such as an

Arkansas stone). Do not try to file or grind this

part.

REASSEMBLY:

NOTE

Use all new seals when

assembling motor. Lubricate

the seals with petroleum jelly

before assembly.

Do not

stretch seals before installing.

together. Bearing race must rotate freely when

1. INSTALL PLUG (20) AND SEAL (21), IF REMOVED.

in piston.

a. If plug (20) and seal (21) were removed,

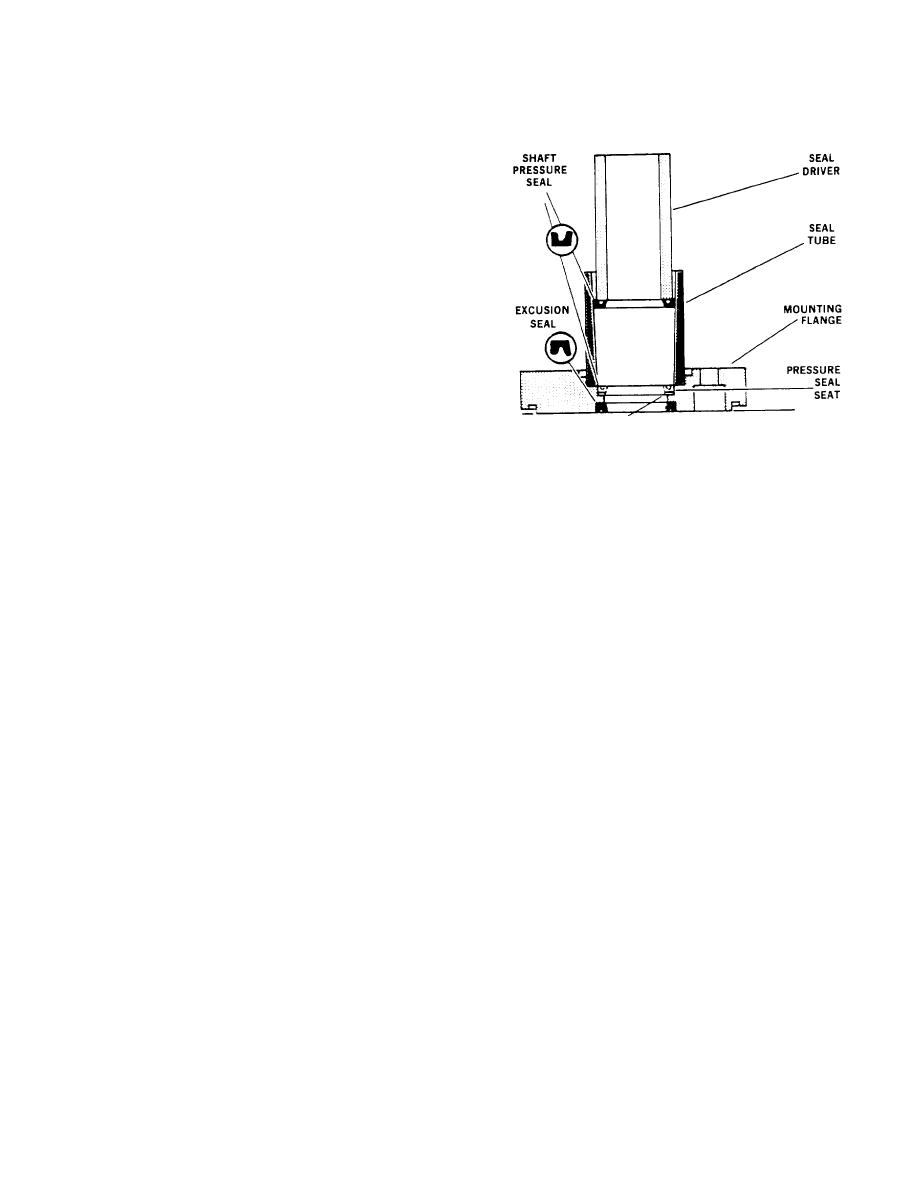

3. INSTALL MOUNTING FLANGE (13) AND SEALS.

lubricate seal and install it on plug. Push plug

into housing so plug and housing are flush. Be

a. Install dust seal (14) in the flange (13) as shown.

careful not to damage seal (21).

Press seal into place carefully, using a tool which

will provide proper guiding and positioning to

NOTE

eliminate damage to rubber portion of distortion

metal container.

Do not allow oil to get into

b. Lubricate I.D. of seal tube and O.D. of shaft

tapped holes.

pressure seal (15) with light film of clean

petroleum jelly. Align small I.D. end of seal tube

2. INSTALL OUTPUT SHAFT (17), NEEDLE THRUST

with seal seat in mounting flange.

Install

BEARING (19) AND BEARING RACE (18).

pressure seal (15) in tube with lip of seal face up

as shown. Insert seal driver in tube and firmly

a. Lubricate output shaft (17) with hydraulic oil.

push seal seat with a rotating action.

Install shaft in housing (11).

b.

Install needle thrust bearing (19) then bearing

race (18) on shaft (17). Pull shaft partially out

of housing, then push all three parts in housing

15-138