TM 5-3810-306-34

CAUTION

CAUTION

After installing seal in flange,

Do not stretch seals before

examine seal condition.

If

installing them in groove.

damaged

or

improperly

NOTE

installed, you must replace it

before

continuing

with

To aid in installation of seals,

reassembly.

apply a light coating of clean

c. Install 1.9375 in. (4.92 cm) diameter seal (16) in

petroleum to seal before

flange (13).

installing.

d. Apply Loctite to bolts (12).

b. Pour approximately 35 cc of hydraulic oil in

output shaft cavity.

e. Before installing flange (13) with seal assembly

over shaft, place protective sleeve or bullet over

c. Install 2.875 in. (7.3 cm) diameter seal (10) in

shaft. Then lubricate space between dust seal

housing seal groove and install wear plate (9) on

(14) and pressure seal (15) as well as lips of

housing (11).

both seals.

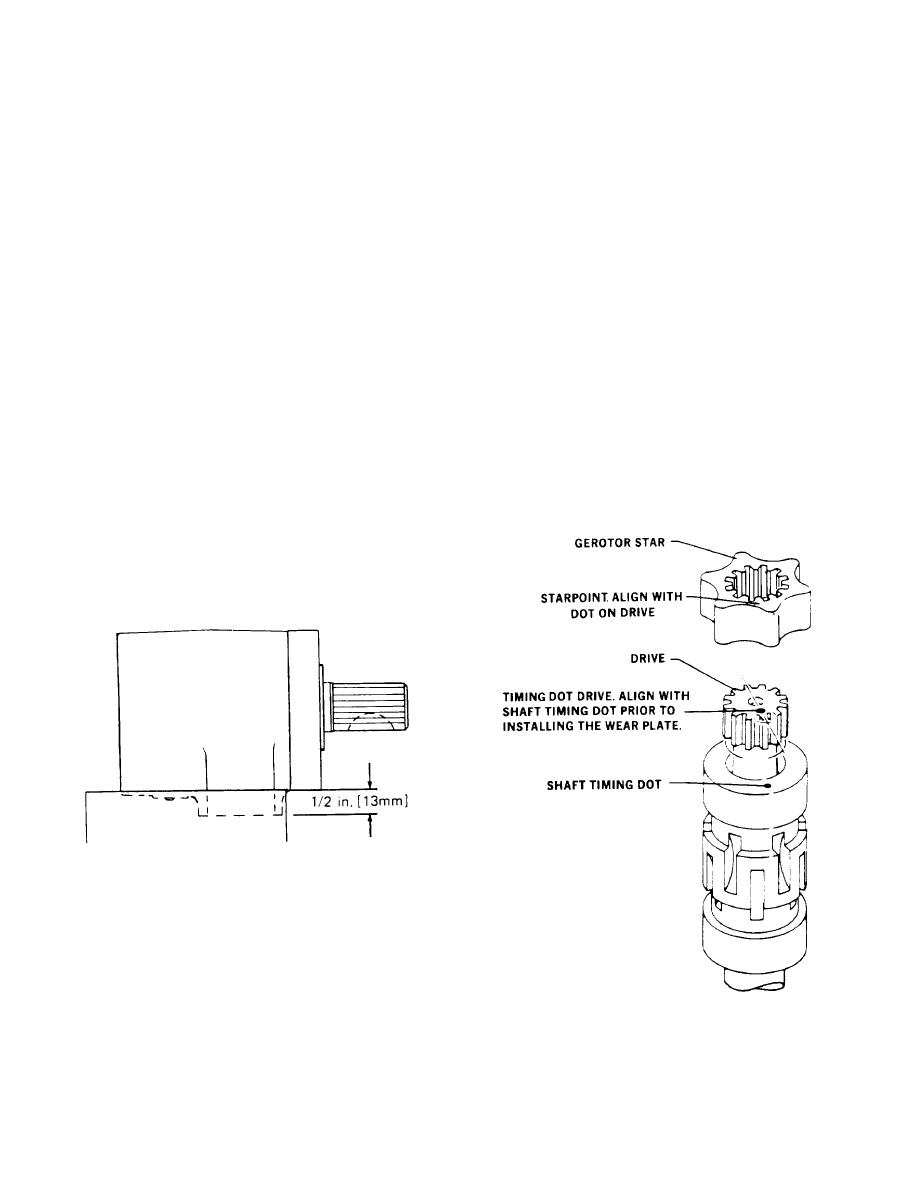

d. Install splined drive (8). Use felt tip marker to

f. Install flange (13). Rotate flange slowly while

mark one drive tooth. Align this tooth with the

pushing down over shaft. Be careful not to invert

timing mark on shaft. Refer to Motor Timing

or damage seals.

figure below.

g. After removing bullet, clamp motor in vice as

shown. Ensure shaft cannot fall out. Install

capscrews (12) and torque immediately 250 in-

lbs (28 Nm).

4. INSTALL SPLINED DRIVE (8) AND WEAR PLATE

(9).

a. Clamp housing in a vise, gerotor end up. Refer

to step la of disassembly for correct clamping

procedure.

15-140