TM 10-3930-641-10

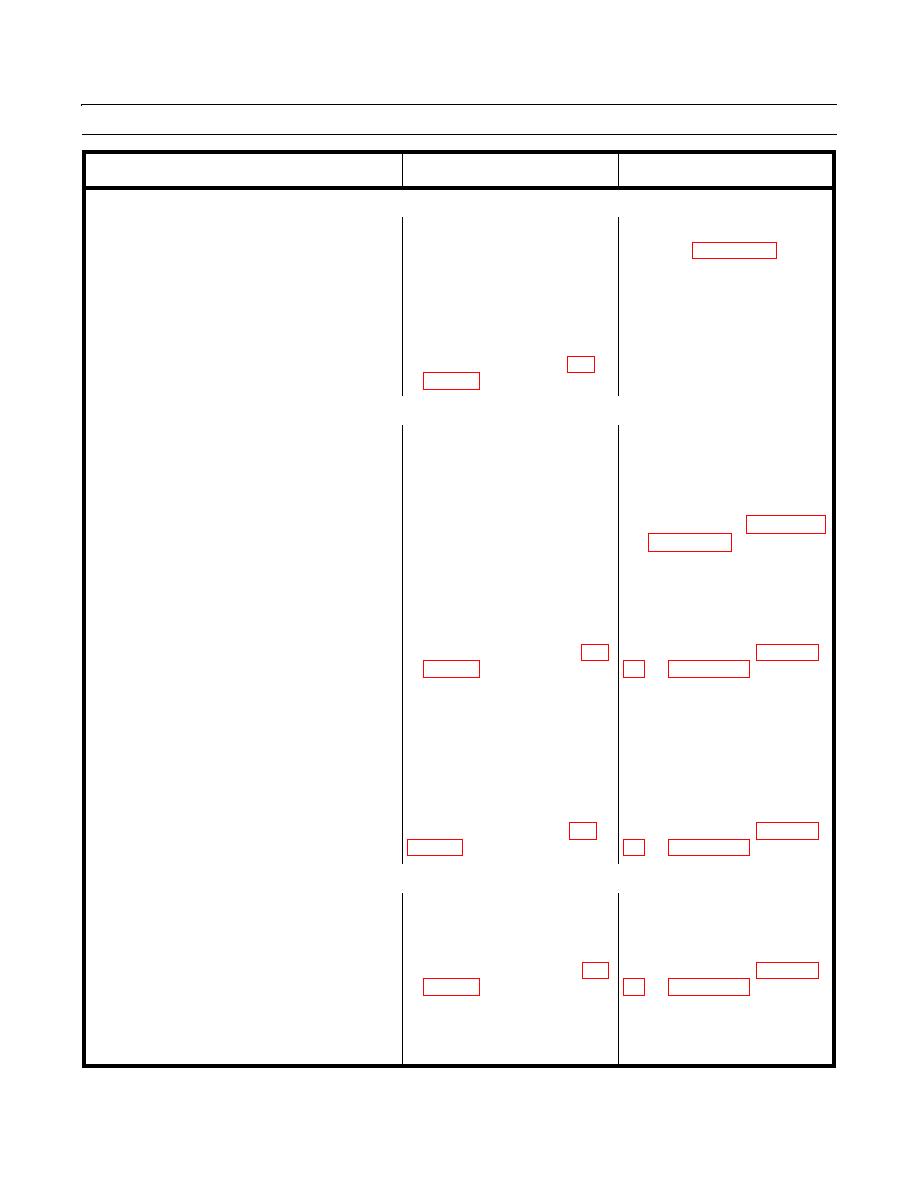

TROUBLESHOOTING PROCEDURES - CONTINUED

0010 00

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE - CONTINUED

1. Check air filter indicator.

If indicator is illuminated, service

13. Excessive Exhaust Smoke (at Normal

precleaner (WP 0012 00) and

Operating Temperature).

retest. If problem still exists, go

to test step 2.

2. Check for restrictions in

Remove restrictions. If problem

exhaust system.

still exists, go to test step 3.

3. Check engine oil level (WP

If oil level is above FULL, notify

Organizational Maintenance.

HYDRAULIC SYSTEM

1. Inspect lines and fittings for

If leaks are found, notify

1.

Hydraulic System Will Not Lift Load or

Will Not Lower Load Correctly.

leaks.

Organizational Maintenance. If

problem still exists, go to test step

2.

Lubricate as needed (WP 0011 00

2. Inspect mast sliding blocks,

rollers, and chains for correct

and WP 0012 00).

lubrication.

1. Inspect lines and fittings for

If leaks are found, notify

2.

Lift or Tilt Cylinders Do Not Hold Position

leaks.

Organizational Maintenance.

with Hydraulic Control Levers in Neutral

Position.

1. Check hydraulic oil level (WP

Add oil as necessary (WP 0011

3.

Oil Temperature Is Too High Hydraulic

Oil High Temperature Indicator Light

still exists, go to test step 2.

Comes On.

If problem still exists, notify

2. Lengthen unloaded return trip

Organizational Maintenance.

to give hydraulic cooling

system time to cool oil. Park

machine, lower mast all the

way, and run engine at high

idle.

Check hydraulic oil level (WP

Add oil as necessary (WP 0011

4.

Noisy Hydraulic Pump.

STEERING

1. Ensure that shipping link is not

Notify Organizational

1.

Machine Doesn't Turn When Steering

Wheel Is Turned.

installed.

Maintenance. If problem still

exists, go to test step 2.

2. Check hydraulic oil level (WP

Add oil as necessary (WP 0011

Allow hydraulic oil to warm up to

If steering wheel is still hard to

2.

Steering Wheel Is Hard To Turn.

normal operating temperatures.

turn, notify Organizational

Maintenance.