TM 5-3810-306-34

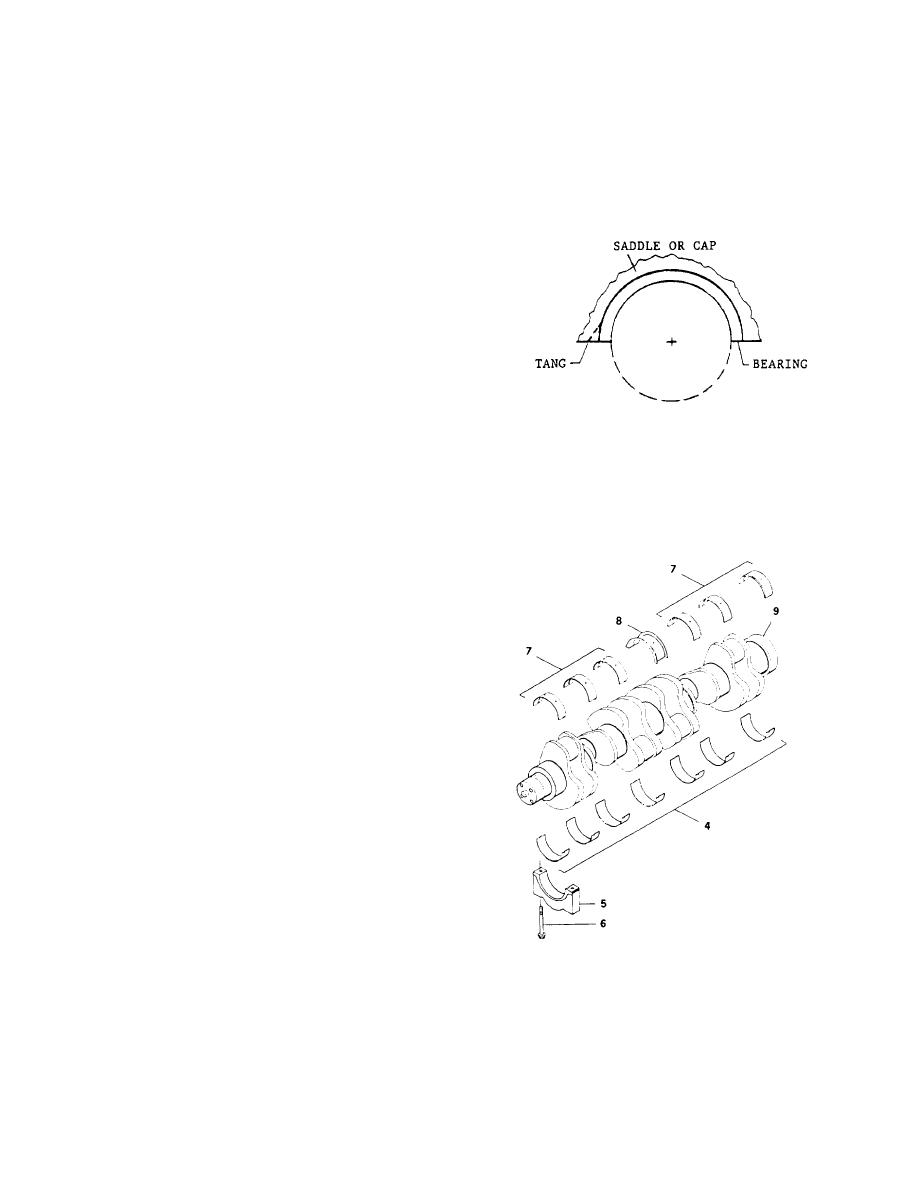

2. INSTALL BEARINGS (7), (8) AND (11),

drop crankshaft on bearing.

a. If removed, using a 1/2 in. center punch, install

b. Install crankshaft (9) taking care not to damage

piston cooling nozzles even with or below

thrust/main bearing (8).

bearing saddle surfaces in block.

4. INSTALL LOWER BEARINGS (4) AND (8) AND

CAPS (5).

NOTE

Upper bearings (7) and (8) contain an

oil hole. Lower bearings (4) do not.

NOTE

All bearings are marked on back to

indicate either standard (STD) or

oversize (OS). Use only appropriate

size required.

b. Install new bearings (7) in bearing saddles.

Make sure tang of bearings are in slot of bearing

a. Install new lower main bearings (4) and (8) into

saddle.

caps (5). Make sure tang of bearing shell is in

slot of cap.

c.

Install new combination thrust/main bearing (8)

in center journal saddle.

b. Lubricate bearings (4) and (8) with Lubriplate

105. Do not lubricate back of bearings.

CAUTION

Prevent dirt from mixing with

lubricant.

(Dirty lubricant will

accelerate bearing wear.)

d. Lubricate bearings (7) and (8) with Lubriplate

105. Do not lubricate back of bearings.

e. Clean crankshaft (9) bearing surfaces using a

lint free cloth.

f.

Install bearings (11) in rods (10) and caps (1).

Apply light film of Lubriplate 105 to bearing

surfaces.

3. INSTALL CRANKSHAFT (9)

a. Using lifting strap that will not damage

crankshaft (9) lower into position avoiding not to

4-26