TM 5-3810-306-34

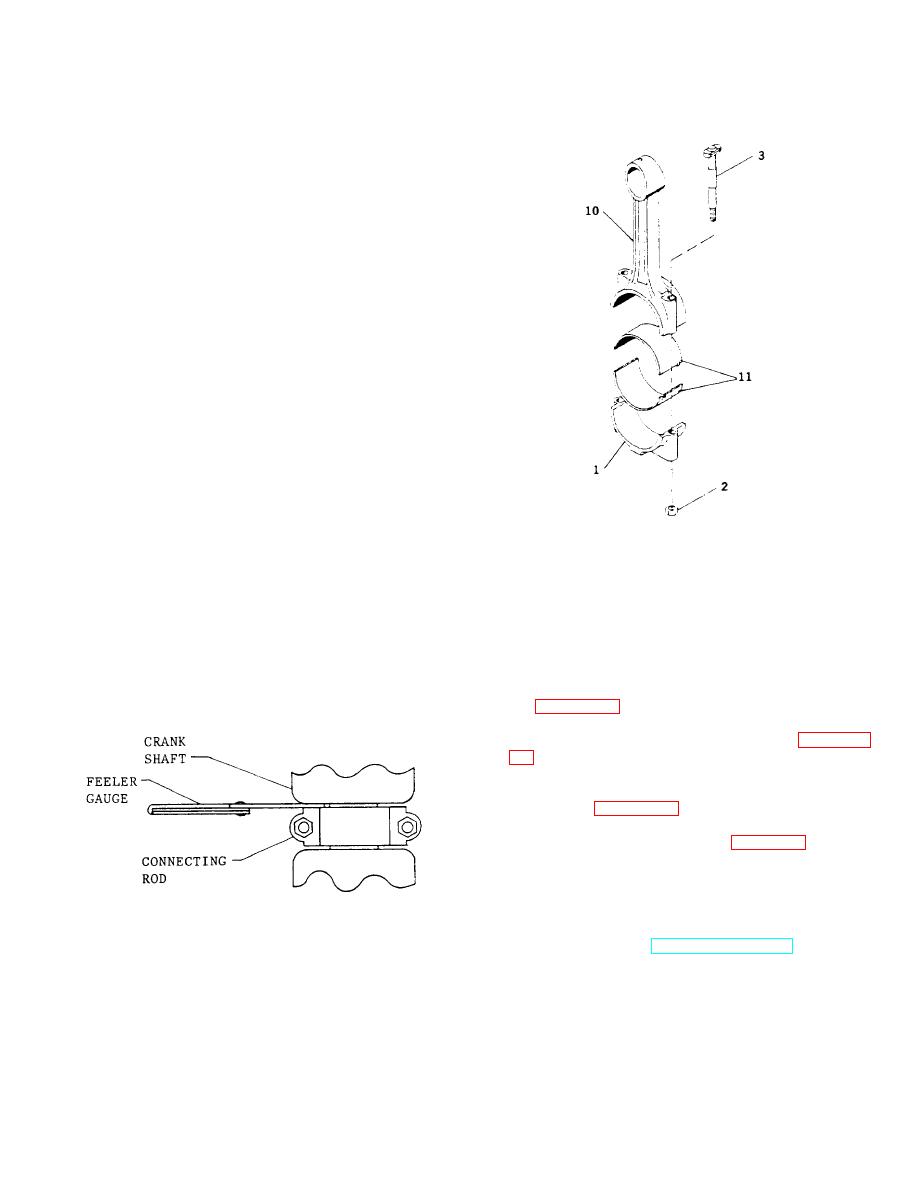

b. Pull connecting rod (10) onto crankshaft (9)

journal.

c.

Apply clean engine oil to lubricate threads of

bolts (3) of connecting rod (10).

NOTE

The number stamped on rod (10) and

cap (1) at parting line must match and

be installed on camshaft side of

engine.

d. Install rod cap (1) and start connecting rod nuts

(2).

e. Lubricate under connecting rod nuts (2) with

clean engine oil.

f.

Alternately tighten rod nuts (2) to pull rod cap (1)

into position.

g. Torque rod nuts (2) evenly n three steps.

First to 30 ft-lbs (40 Nm)

Second to 60 ft-lbs (80 Nm)

Final torque to 88 ft-lbs (117 Nm)

j.

Check crankshaft for freedom of rotation as caps

h. Shake connecting rod (10) and cap (1) to verify

(1) are installed one at a time. If crankshaft

side clearance.

does not rotate freely check bearing installation

and size.

i.

Measure total side clearance with a feeler gauge

between crankshaft and connecting rod.

k.

Install all six caps (1).

min .004 (.1 mm)

7. INSTALL OIL PAN AND SUCTION TUBE. (REFER

max .012 (.3 mm)

TO PAGE 4-57.)

8. INSTALL FRONT COVER. (REFER TO PAGE 4-

9. INSTALL FLYWHEEL HOUSING AND REAR SEAL.

(REFER TO PAGE 4-29.)

10. INSTALL ENGINE. (REFER TO PAGE 4-2.)

11. INSTALL ENGINE HOOD. (REFER TO TM 5-3810-

306-20.)

12. CONNECT NEGATIVE BATTERY CABLE

AT

SHUNT. (REFER TO TM 5-3810-306-20.)

END OF TASK

4-28