TM 5-3810-306-34

c.

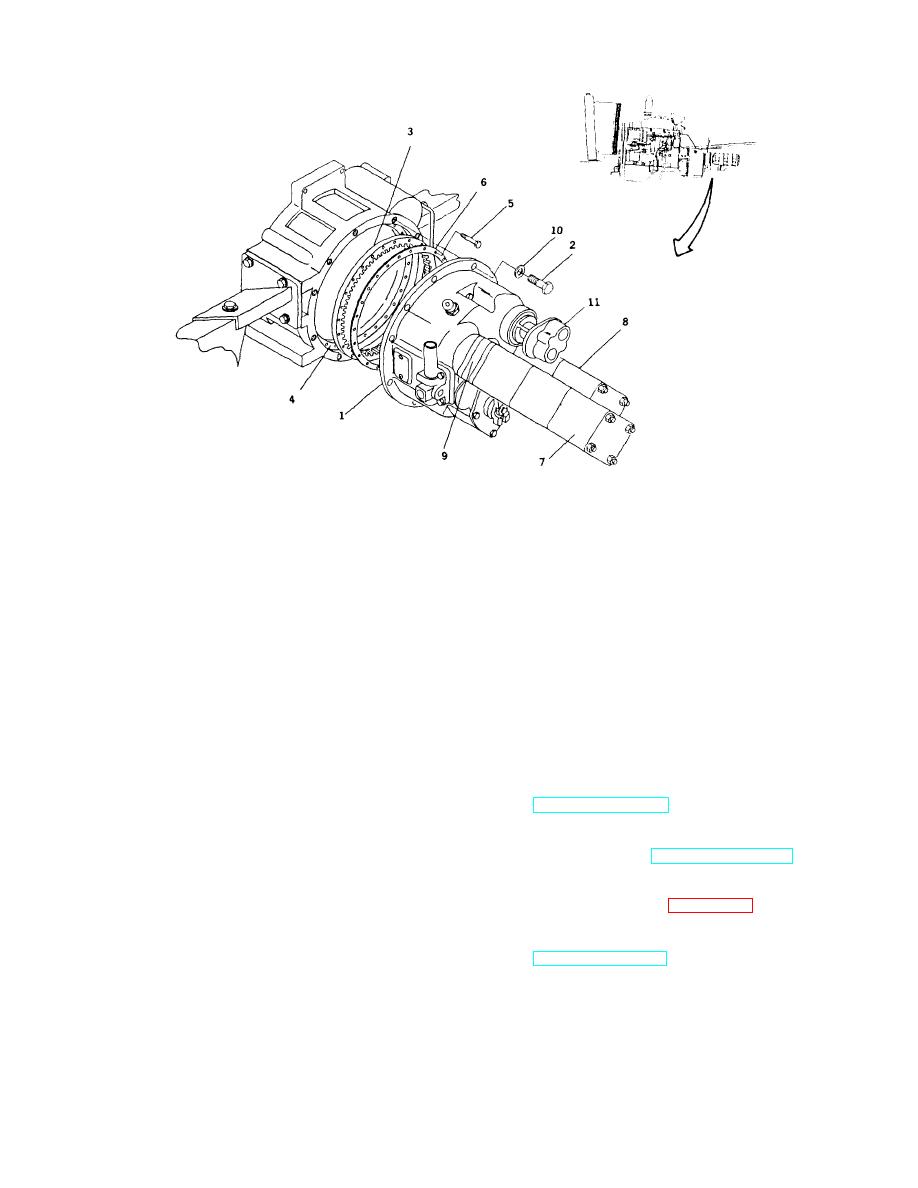

Install backing ring (6) and thirty-two special

d. Measure engine crankshaft end play after

screws (5). Tighten screws to 23-25 ft-lbs (30-

assembly of torque converter. This value must

33 Nm). The special screws are to be used for

be within one thousandth (.001) of an inch of end

ONE installation only. If screws are removed for

play recorded (Step a) before assembly of

any reason, they MUST BE REPLACED.

torque converter.

Remove epoxy left in flywheel hole with the

proper tap and clean with solvent. Dry hole

5. CONNECT TAGGED ELECTRICAL WIRES TO

thoroughly and use a NEW screw for

TORQUE CONVERTER.

reinstallation.

6. REMOVE

CAPS

AND

PLUGS,

INSTALL

4. USING AN ADEQUATE LIFTING STRAP AROUND

HYDRAULIC LINES TO TWO HYDRAULIC PUMPS

TORQUE CONVERTER.

LIFT AND MOUNT

(7) AND (8) AND CONVERTER CHARGING PUMP

TORQUE CONVERTER TO FLYWHEEL HOUSING.

(11).

SECURE WITH TWELVE BOLTS (2) AND

WASHERS (10).

7. INSTALL PROPELLER SHAFT. (REFER TO TM 5-

3810-306-20.)

a. Measure and record engine crankshaft end play

at flywheel.

8. INSTALL REAR DECKING AND HOOD.

(REFER

TO TM 5-3810-306-20.)

b. Assembly torque converter to engine flywheel by

sliding converter into position by hand before

9. CONNECT NEGATIVE BATTERY CABLE

AT

fastening housing attachment screws. This may

SHUNT. (REFER TO TM 5-3810-306-20.)

require more than one trial to match drive gear

teeth.

Pulling converter into position with

10. SERVICE THE TRANSMISSION

HYDRAULIC

housing attachment bolts is not recommended.

SYSTEM. (REFER TO PAGE 7-61.)

c.

Install twelve bolts (2) and washers (10) securing

11. SERVICE CRANE HYDRAULIC SYSTEM. (REFER

torque converter to flywheel housing.

TO LO 5-3810-306-12.)

12. TEST FOR PROPER OPERATION AND INSPECT

FOR LEAKS.

END OF TASK

7-4