TM 5-3810-306-34

INSPECTION:

1. INSPECT ALTERNATOR COMPONENTS.

(6) If ohmmeter reading is above 3.0, rotor winding

has excessive resistance.

a.

Inspect pulley for cracks and wear.

(7) If ohmmeter reading is below 2.4, rotor winding

b.

Inspect fan for wear and damaged vanes.

is shorted.

c.

Inspect rotor for corrosion and wear.

NOTE

d.

Inspect brushes for wear.

If the rotor assembly is not defective

but the generator fails to supply rated

e.

Check rotor assembly as follows:

output, then defect is in diode,

rectifier, stator, or voltage regulator.

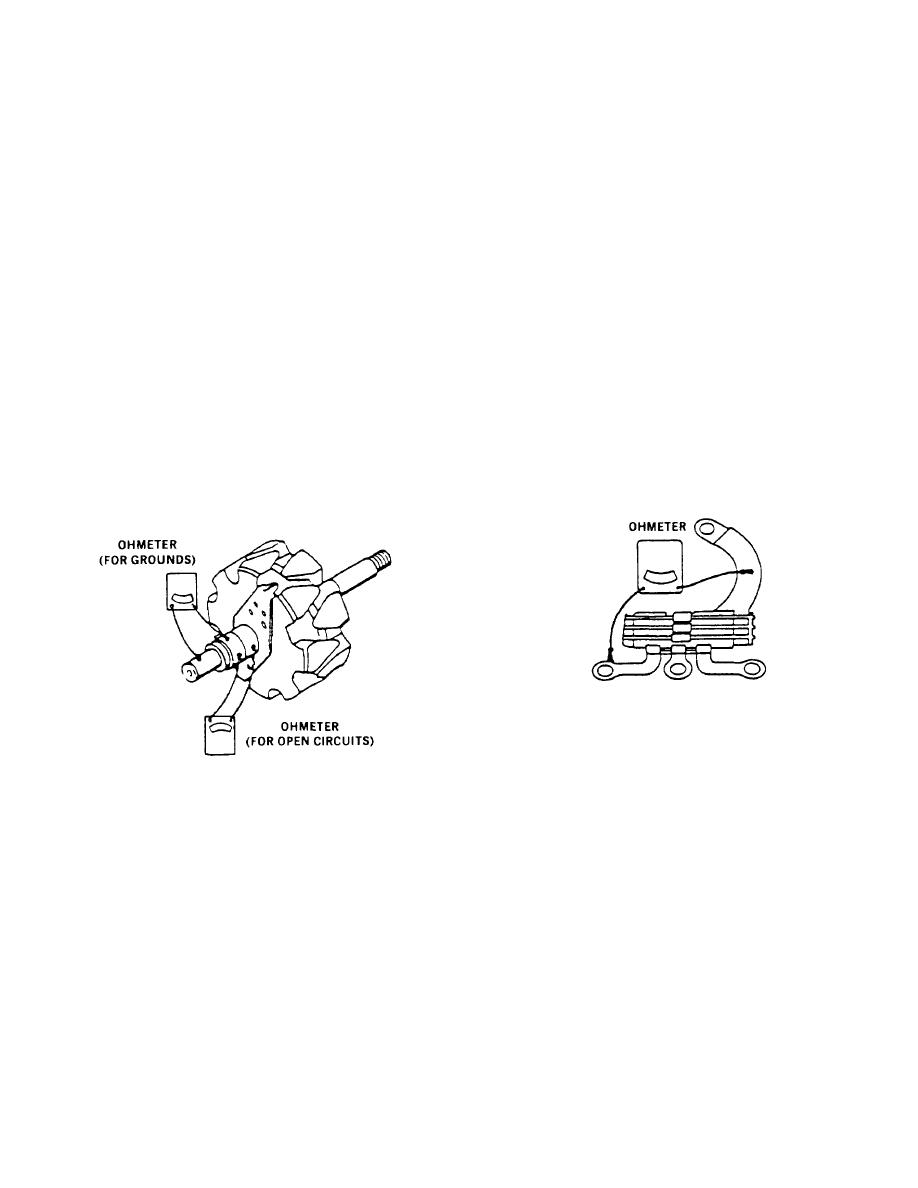

(1)

Connect ohmmeter to each slip ring.

f. Check diodes as follows:

(2)

If ohmmeter reading is high (infinite),

then rotor winding is open.

(1) Connect ohmmeter (having a 1-1/2 volt cell) to

single side connector and one of three

(3)

Connect ohmmeter from one slip ring to

connectors.

shaft.

(2) Observe and record reading on lowest range

(4)

If ohmmeter is low, then rotor winding is

scale and reverse leads to same two connectors.

grounded.

(3) Observe ohmmeter reading.

(4) If readings are the same, replace diode. A good

diode will give one high and one low reading.

(5)

Check rotor winding for short-circuit by

connecting ohmmeter to each slip ring.

6-4