TM 10-3930-675-20-2

0191 00-5

TOPHANDLER REPLACEMENT - CONTINUED

0191 00

REMOVAL - CONTINUED

20.

Reinstall tilt cylinder mounting hardware (pin, lockwasher, and bolt) on each side of tophandler to provide secure stow-

age of items while tophandler is in transit.

INSTALLATION

1.

Remove tiedowns from tophandler and trailer.

NOTE

It is crucial that RTCH and trailer be in alinement. If time is not taken to ensure accurate alinement, installa-

tion of tophandler to boom will be very difficult because pivot shafts will bind while being installed.

2.

Position RTCH directly behind trailer, so that tophandler and RTCH boom are in line with each other.

3.

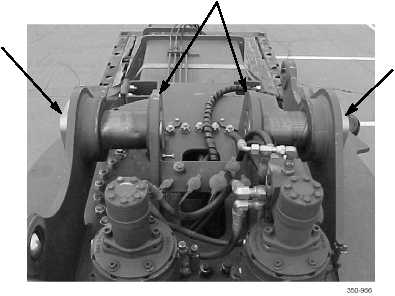

From each side of tophandler, remove tilt cylinder mounting hardware that was stowed while tophandler was in transit:

pin, lockwasher, and bolt. Discard lockwashers if new lockwashers are available.

4.

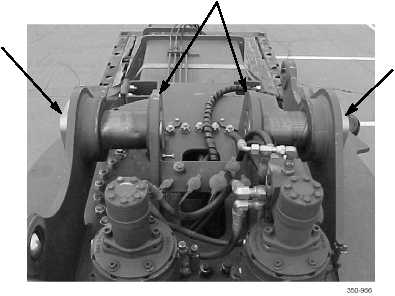

Remove tophandler mounting hardware: pivot shafts (10), lockwashers (13), and bolts (12). Discard lockwashers if new

lockwashers are available.

NOTE

•

Because tophandler junction box is disconnected from RTCH electrical system, error codes will appear

on driver’s ECS display screen when boom is operated. These error codes will include numbers 245-

265 as well as others. To continue operation, reset driver’s display and use override button on right side

of joystick housing (TM 10-3930-675-10).

•

If alinement of boom extension to tophandler does not look OK, reposition RTCH and ensure accurate

alinement before proceeding.

10

5

10