TM 5-3810-306-34

2. STONE OUT MINOR BLEMISHES AND POLISH

WITH A FINE CROCUS CLOTH.

3. CLEAN WITH SOLVENT AND DRY WITH

COMPRESSED AIR ANY PARTS THAT HAVE

BEEN STONED AND POLISHED.

4. INSPECT BARREL CAREFULLY FOR SCORING.

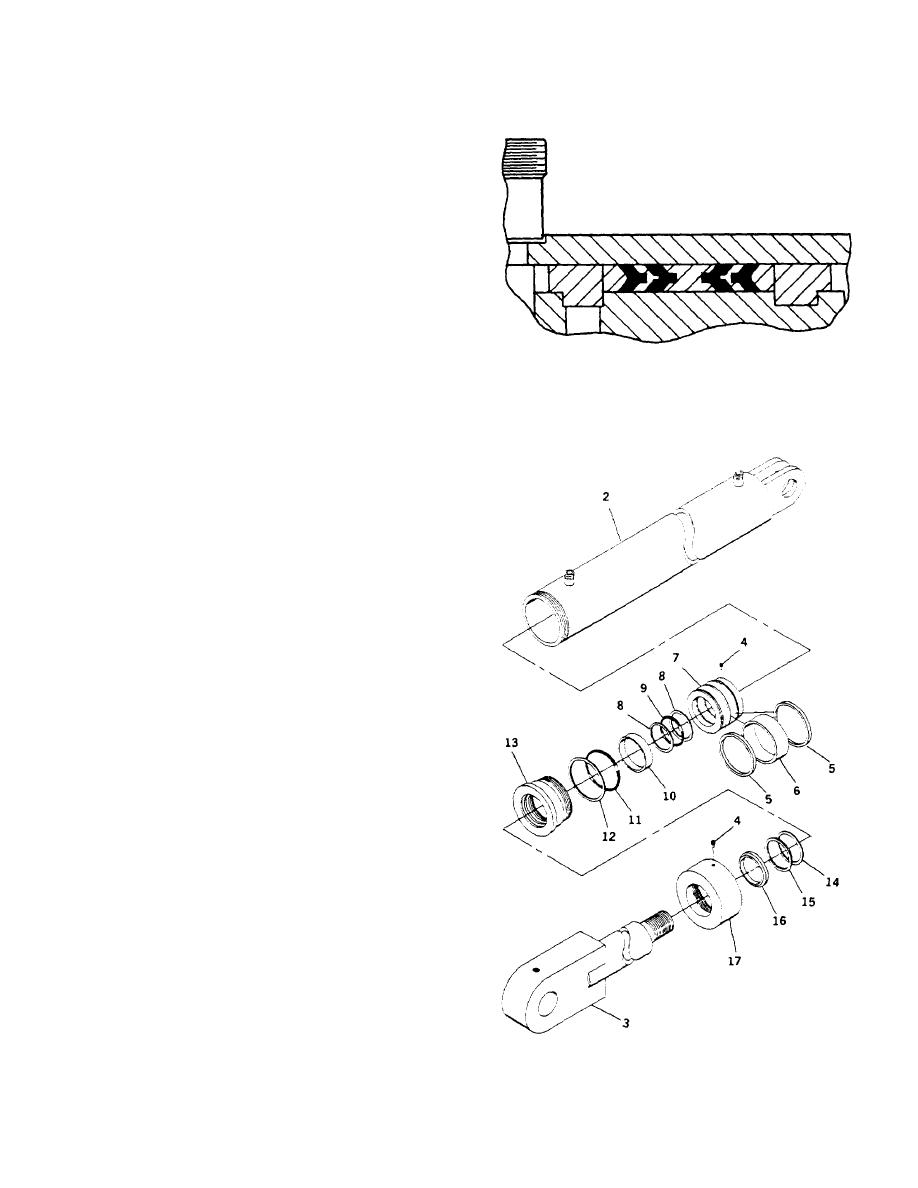

REASSEMBLY:

WARNING

When installing new seals and rings,

avoid stretching seals or scratching

4. IF EXISTING PISTON (7) AND ROD (3) ARE TO BE

grooved or gland surfaces.

USED, PROCEED AS FOLLOWS:

NOTE

a. Install piston (7) onto rod (3).

Lubricate new seals and rings with

clean hydraulic oil.

1. LUBRICATE AND INSTALL A NEW WIPER SEAL

(16) INTO INSIDE OF LOCK RING (17) AND SLIDE

LOCK RING ONTO ROD (3).

2. INSTALL HEAD (13) AND NEW SEALS ON ROD

(3).

a. Lubricate and install a new packing (11) and

backup ring (12) onto outside of head (13).

b. Lubricate and install a new wear ring (10) on

inside of head.

c.

Lubricate and install a new rod seal (15),

grooved end first, into inside of head (13).

Lubricate and install a new buffer seal (14).

d. Slide head onto rod (3).

3. INSTALL NEW SEALS AND BACKUP RINGS ON

PISTON (7).

a. Lubricate and install new ring (6) and seals (5)

onto outside of piston (7). Ensure the seal

assembly is installed as shown.

b. Lubricate and install two new back-up rings (8)

and new packing (9) on inside of piston (7).

10-11