TM 5-3810-306-34

INSTALLATION:

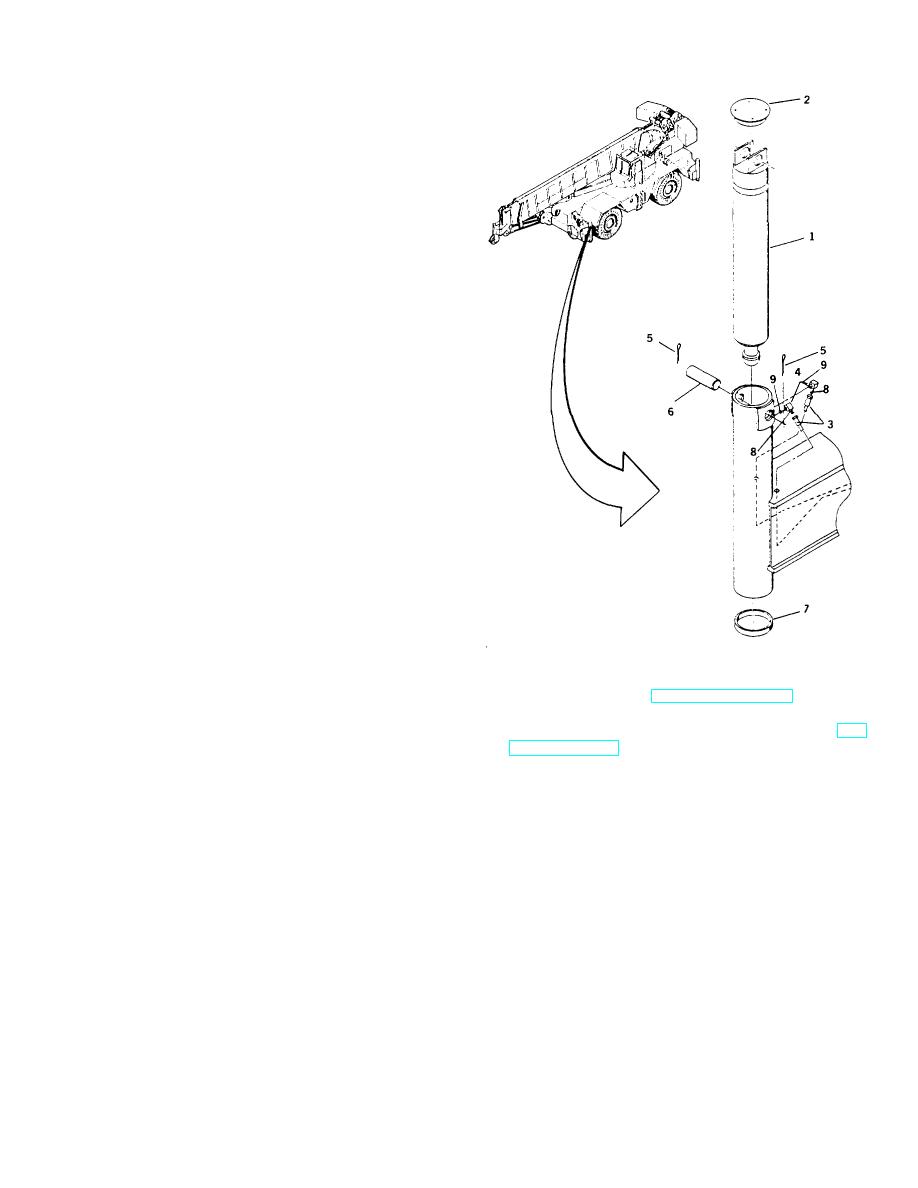

1. INSTALL JACK CYLINDER (1).

a. Install new wear ring (7) in groove in bottom of

cylinder tube.

b. Place a hydraulic jack under cylinder tube.

c.

Using a lifting device, lower jack cylinder into

tube aligning ports with cut-out in tube.

d. Raise hydraulic jack to take up weight of cylinder

and remove lifting device.

e. Lower cylinder (1) into tube until pin (6) can be

installed. Use care not to damage wear ring (7)

or dislodge it.

f.

Coat pin with Never-Seeze and install pin (6) and

two new cotter pins (5) securing cylinder (1) to

tube.

g. Remove the hydraulic jack.

NOTE

Coat new performed packing with

clean hydraulic oil and fittings

threads with Loctite #545.

h. Install hydraulic fittings (4) and new packings (9)

in ports of cylinder.

2. CONNECT NEGATIVE BATTERY CABLE

AT

CAUTION

SHUNT. (REFER TO TM 5-3810-306-20.)

Ensure piston side (extend) of

3. ACTIVATE HYDRAULIC SYSTEM. (REFER TO TM

cylinder is connected to solenoid

5-3810-306-10.)

valve. Reversal of port connection of

rod (retract) and piston (extend)

4. EXTEND AND RETRACT JACK CYLINDER AS

could result in damage to cylinder as

DESCRIBED

UNDER

OUTRIGGER

BEAM

very high pressure will occur.

INSTALLATION.

5. CHECK

FOR

SMOOTH

OPERATION

OF

i.

Connect hydraulic lines (3) And new packings (8)

CYLINDER.

to fittings as tagged during removal.

6. CHECK ALL HYDRAULIC CONNECTIONS AND

j.

Install jack cylinder access cap (2) with

HOSES FOR EVIDENCE OF LEAKAGE.

weatherstrip cement applied in three beads

approximately 120 apart.

END OF TASK

11-16