TM 5-3810-306-34

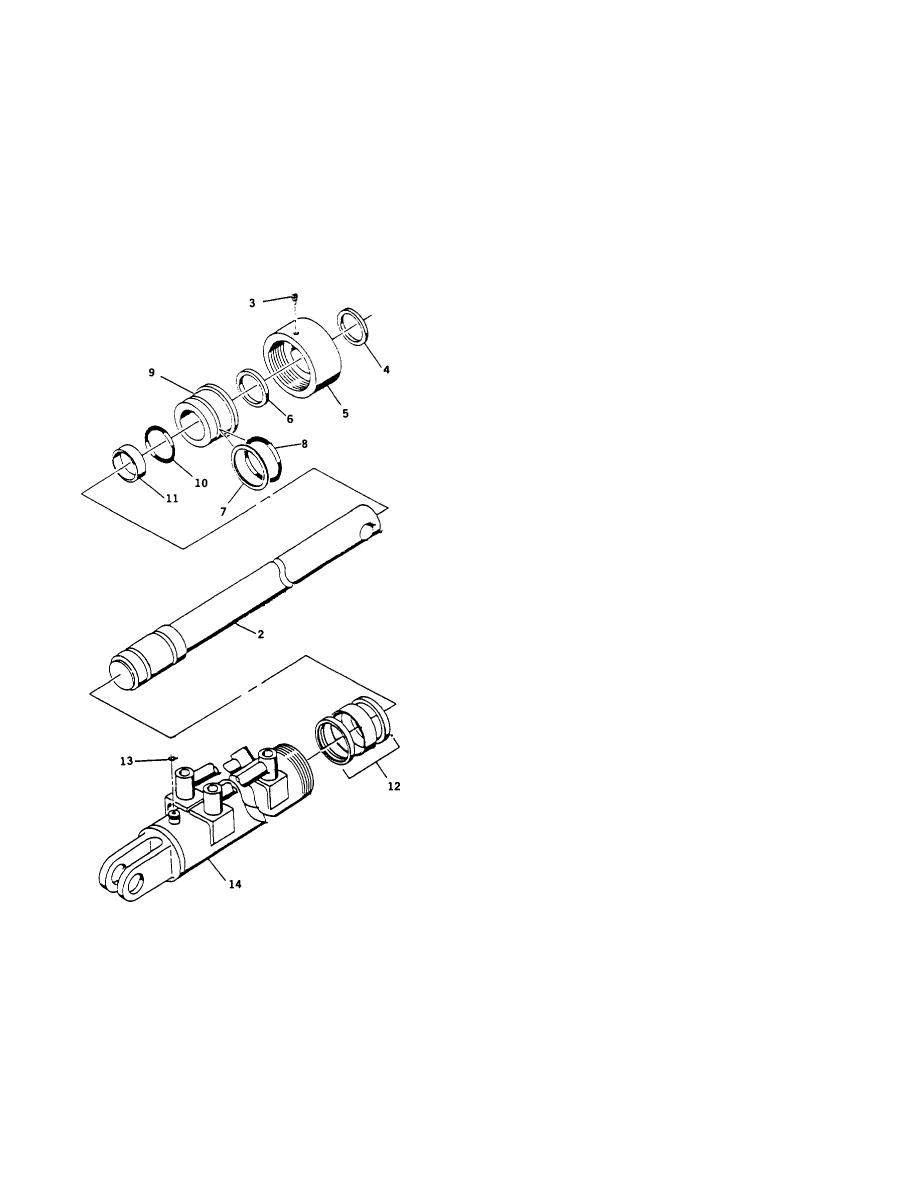

a. Remove the seals from the piston (2).

c.

Remove head (9) from rod. Remove packing (8)

and back-up ring (7) from outside of head.

Remove wear ring (11), rod seal (6) and buffer

NOTE

seal (10) from inside of head.

Aligning discarded seals and rings in

CLANING AND INSPECTION:

order of disassembly will facilitate

installation of new seals and rings.

WARNING

b. Remove lock ring (5) from rod (2). Remove

Dry cleaning solvent P-D-680 is toxic

wiper seal (4) from inside of the lock ring (5).

and flammable.

Wear protective

goggles and gloves and use only in a

well ventilated area. Avoid contact

with skin, eyes, and clothes and do

not breathe vapors. Do not use near

open flame or excessive heat. The

flash point is 100F-138F (380-590C).

If you become dizzy while using

cleaning solvent, get fresh air

immediately and get medical aid. If

contact with eyes is made, wash your

eyes with water and get medical aid

immediately.

Compressed air used for cleaning

purposes will not exceed 30 psi. Use

only with effective chip guarding and

personal

protective

equipment

(goggles/ shield, gloves, etc.).

1. CLEAN ALL PARTS WITH SOLVENT AND DRY

WITH COMPRESSED AIR. INSPECT ALL PARTS

FOR SERVICEABILITY.

CAUTION

Before installing new seals and rings,

clean all surfaces and carefully

remove burrs and nicks.

Parts

displaying excessive wear or damage

should be replaced.

11-12