TM 5-3810-306-34

CAUTION

Exercise extreme care when handling

or setting down cylinder rod.

Damage to rod surface may cause

unnecessary

maintenance

and

expense.

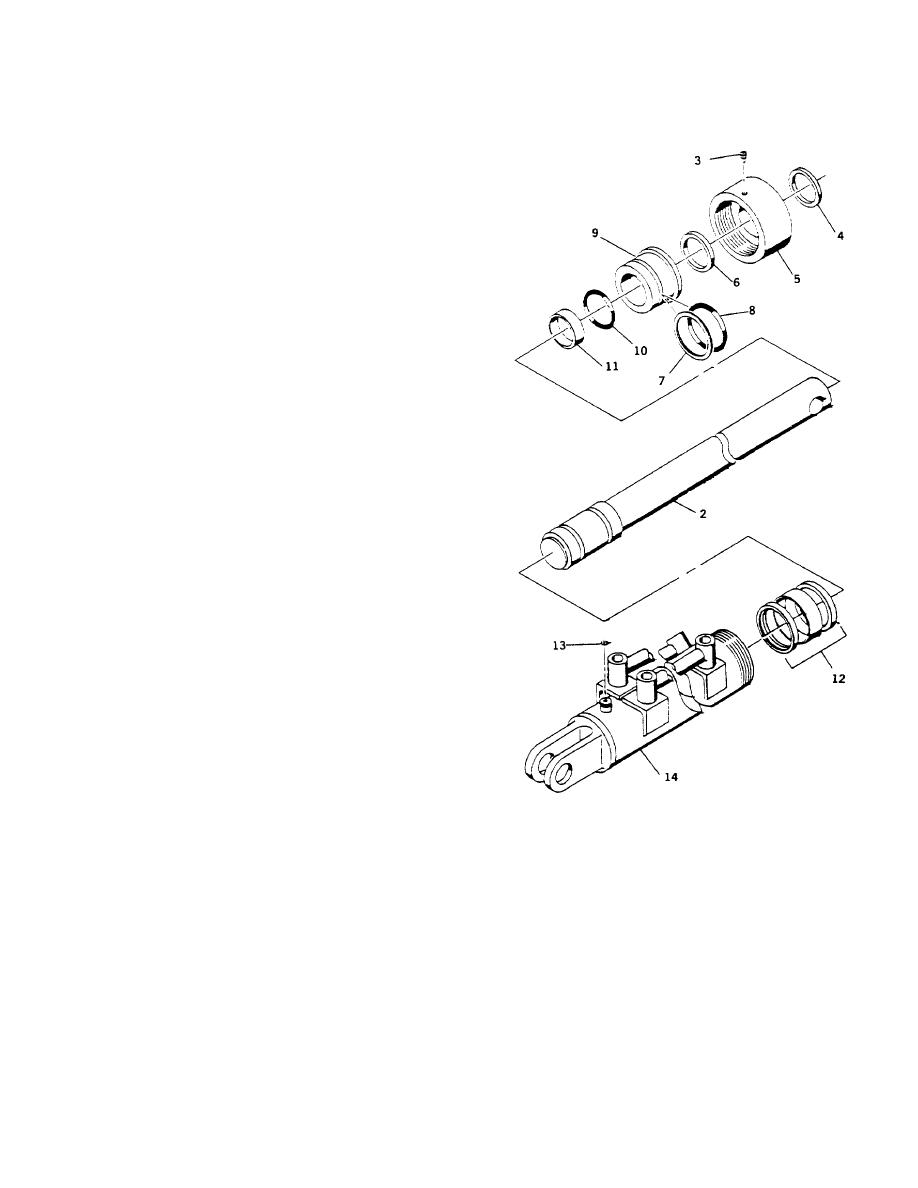

3. INSTALL CYLINDER ROD ASSEMBLY INTO

CYLINDER BARREL WITH A TWISTING MOTION.

SEAT HEAD IN CYLINDER BARREL.

4. CLEAN OIL FROM THREADS OF LOCK RING (5).

COAT THREADS WITH NEVER-SEEZ (PASTE

TYPE) LUBRICANT.

5. IF EXISTING LOCK RING (5) AND BARREL (14)

ARE TO BE USED, PROCEED AS FOLLOWS:

a. Screw lock ring (5) onto barrel (14).

b. Using strap wrench, tighten lock ring securely

until the setscrew holes align.

c.

Apply Loctite # 271 to setscrew (3) and install

setscrew.

6. IF NEW LOCK-RING (5) OR BARREL (14) IS TO

BE USED, PROCEED AS FOLLOWS:

a. Screw lock ring onto barrel.

b. Using a strap wrench, tighten lock ring securely.

c.

If necessary, drill 0.265-in.

dia.

hole 3/16-in.

(maximum) deep in barrel.

NOTE

Setscrew when installed should be

flush with lock ring.

d. Clean drilled hole of chips and debris.

e. Apply Loctite # 271 to setscrew and install

setscrew (3).

WARNING

Do not use air pressure to cycle or

pressurize cylinder.

7. PRESSURIZE AND CYCLE CYLINDER. CHECK

PROPER OPERATION AND ANY LEAKAGE.

END OF TASK

11-14